It didn’t take you 3 minutes- it took you 10-20 years. However long it took you to learn APT. Mind you- I think APT was an awesome technology and I have a lot of respect for it. I even get to use its modern equivalent on occasion (NX Sequential Mill), but telling someone to whip out APT for a quick de-burr job is like telling them to whip out their thermodynamics text book to fly from SFO to LAX.

You are using NX and commenting on how long it takes to learn APT ?

Let's start with this instance : are we agreed that it is not a simple G02/G03 situation ? If there is a way to program an edge that is simultaneously arced in two planes without using cam, can someone explain ?

(Controls should be powerful enough to do this now, maybe an advance that control people should think about ?)

Kyle, the program that works -- is it a million short lines for the radius at the end of the slot ?

About APT, I don't expect anyone here to use it, all the professionals here are in full-sheep mode. That's fine, but maybe some day someone will do a web search and come across this, maybe a little less closed-minded than the people in this place.

For this part, and other regular-shaped objects, APT is SIMPLE. Drive surface, part surface, check surface.

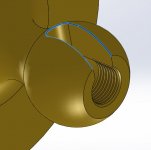

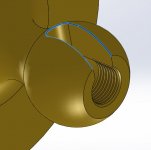

View attachment 278746

The rest is just a bunch of abbreviations, no worse than g-code.

Seriously, five minutes to program this. Ten if you are a beginner.

Define the sphere - center point and radius. Put a plane at the end of the truncated sphere - three points at that length. Put a plane along one edge of the slot, and a plane at the other edge. Define a cylinder tangent to both edges at the end of the slot - center and diameter.

Geometry done, now motions :

Tell the tool to rapid to the drive surface (edge of slot), with the bottom on the part surface (sphere), and touching the check surface (truncated sphere plane.) Feed along the edge plane to the cylinder. Feed along the cylinder to the other edge plane. Feed along the other edge past the truncated sphere plane.

Done. Simple as apple pie, just as easy as writing g-code.

APT is not God's gift to mankind, the solution to world hunger, and the ultimate computer-aided manufacturing pushbutton "gee whiz, it's all done for me !" tool. But it IS a useful and inexpensive way to solve a lot of programming problems. If people have enough independence to overcome the sheeple mentality "That's so difficult ! That's so old ! that's

archaic !" it can be a very efficient way to program a lot of parts.

Did I mention it is free ? Because we, the taxpayers, already paid for it and own it ? In other threads people were going on about how you need to spend $15,000 to do cam. As a small shop, for me that's a no way jose. If they can make F14's and B-1's with this thing, and it's free, that'll do the job for me. I don't mind spending a few hour to learn how it works (how long does it take to "learn" Mastercam ?).

So, you may now return to your regularly scheduled ridicule, but at least the info is out there for people who were not exposed to this years ago.

p.s. Nice looking chamfer