SIM

Titanium

- Joined

- Feb 19, 2004

- Location

- Staten Island NewYork USA

Running a pure copper job in lathe that is giving me grief.

We run a bunch of parts with no problem, then one ripps the material away instead of cutting.

Using sharp, high shear tooling where ever possible, higher Rpms, lots of coolant on ops except threading, (OD single point, ID tap) where we use Cool Tool. I'd give exact SFM, IPR and DOC but we have been up and down so much I can't remember where we are now.

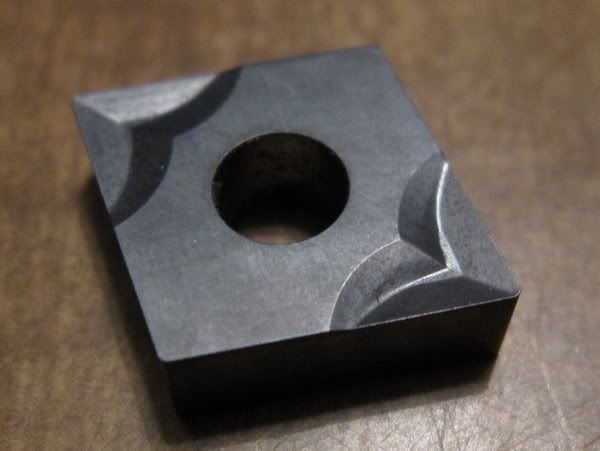

Right now my biggest problem is the simplest, turning the OD. Using a CNGP 432. Thinking of grinding up a HSS tool real sharp, but that CNPG is like a razor. Bad parts are getting pricey...

Thanks for any input.

We run a bunch of parts with no problem, then one ripps the material away instead of cutting.

Using sharp, high shear tooling where ever possible, higher Rpms, lots of coolant on ops except threading, (OD single point, ID tap) where we use Cool Tool. I'd give exact SFM, IPR and DOC but we have been up and down so much I can't remember where we are now.

Right now my biggest problem is the simplest, turning the OD. Using a CNGP 432. Thinking of grinding up a HSS tool real sharp, but that CNPG is like a razor. Bad parts are getting pricey...

Thanks for any input.