Rick Finsta

Stainless

- Joined

- Sep 27, 2017

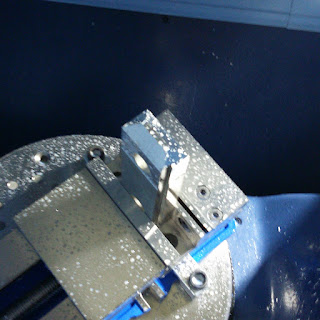

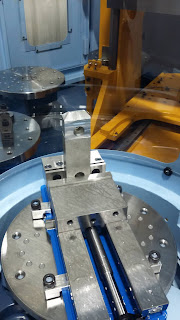

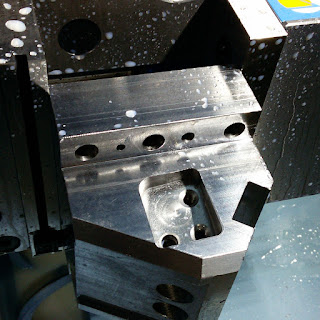

It's 5-axis day!!!!!

We bought this machine back in August, knowing it was going to IMTS. After some floor planning difficulties as we determine the direction we want to go with the business, followed by difficulty getting the concrete pad done in time, we are finally taking delivery today.

More pictures later once the grout is poured and the riggers are out of there. It is shoehorned in a corner but we are moving equipment away form it and tearing down a wall in front of it soon enough. We are building a work cell with this machine, a gantry lathe, and either a 1M Brother Speedio or potentially a bigger VMC or HMC. We will find out more about what kind of stuff we'll be doing in the next few months as we bring new work in, but so far i've got enough P20 prehard part quotes on my desk that we might want something that'll do some hogging.

We bought this machine back in August, knowing it was going to IMTS. After some floor planning difficulties as we determine the direction we want to go with the business, followed by difficulty getting the concrete pad done in time, we are finally taking delivery today.

More pictures later once the grout is poured and the riggers are out of there. It is shoehorned in a corner but we are moving equipment away form it and tearing down a wall in front of it soon enough. We are building a work cell with this machine, a gantry lathe, and either a 1M Brother Speedio or potentially a bigger VMC or HMC. We will find out more about what kind of stuff we'll be doing in the next few months as we bring new work in, but so far i've got enough P20 prehard part quotes on my desk that we might want something that'll do some hogging.

I love that machine. Especially with the PC 4. Congrats and thank you for the order.

I love that machine. Especially with the PC 4. Congrats and thank you for the order.