gt40

Plastic

- Joined

- May 14, 2010

- Location

- BainBridge IS

Howdy- I have been a member of Practical Machinist since 2010. While I have built a half dozen machines including a 40 taper 10hp epoxy granite cnc mill and an 13x40 jet lathe CNC conversion, this is my first "new" machine. I am on Bainbridge Island and it has been interesting. My shop has 200 amp 240 1 phase So I went with a RPC plus transformers on the advice of Peter- the Yamazen Tech. The machine works but I am getting some issues. Stopping the spindle from 16k to zero is causing a regenerative overload error 50 percent of the the time and once in a while from 14k. I went from 10 gauge to 6 gauge main power cord on request of Yamazen but it didn't make any change. FYI, Voltage is 208, 213, 209 leg to leg with the transformers and 107, 203, 108 volts leg to ground. RPC is 25hp and is within Volts variance leg to leg also. At this point not sure what to do. Wondering if something like a line/load reactor may be of help? Any suggestions would be really appreciated!

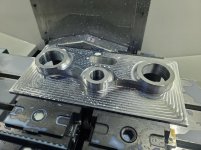

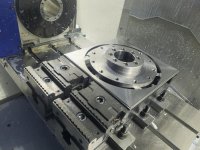

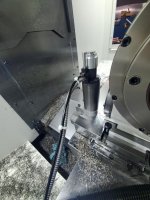

Here are a few pics from the install:

Any suggestions would be really appreciated!

Mark

Here are a few pics from the install:

Any suggestions would be really appreciated!

Mark