Rick Finsta

Stainless

- Joined

- Sep 27, 2017

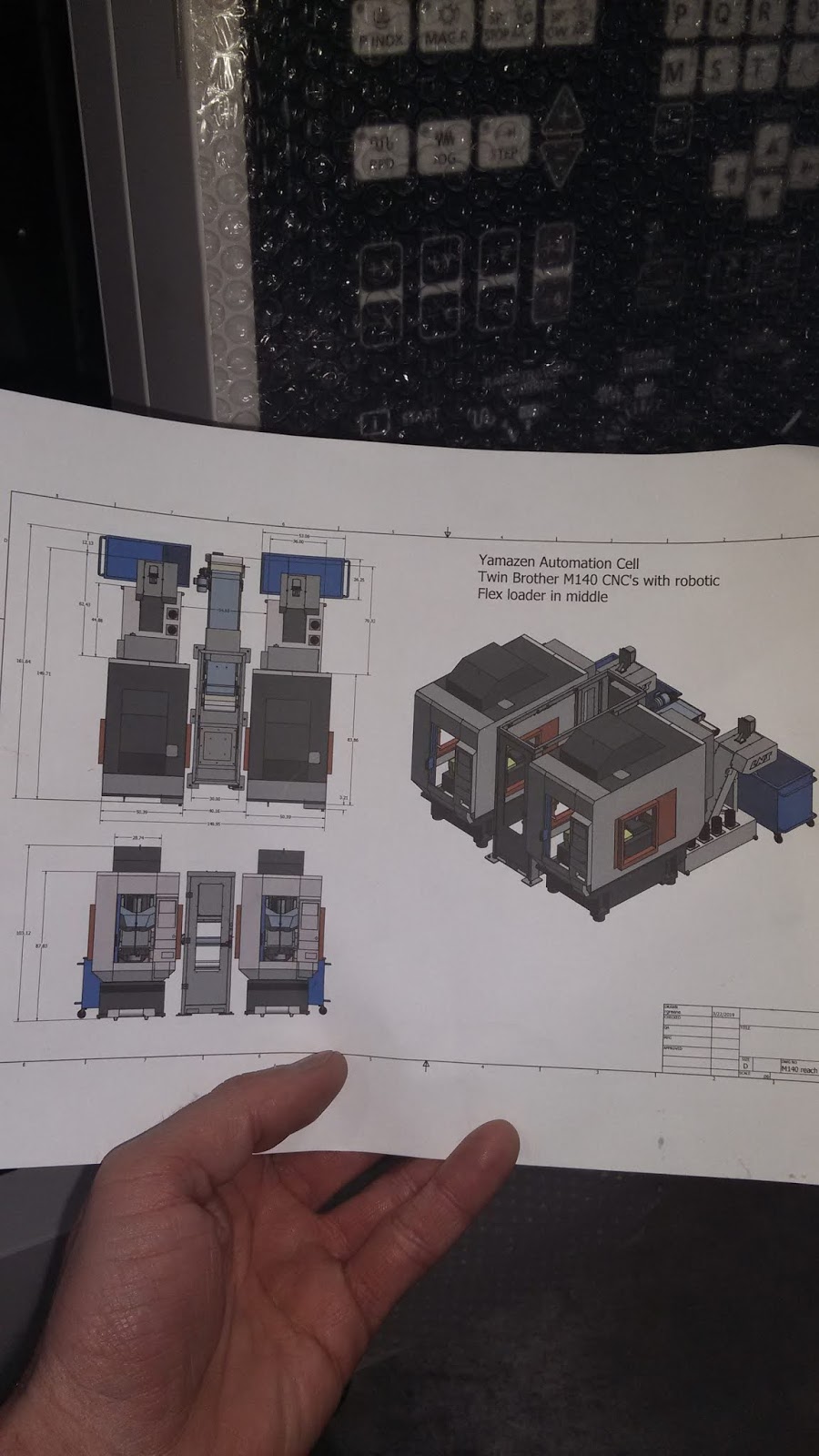

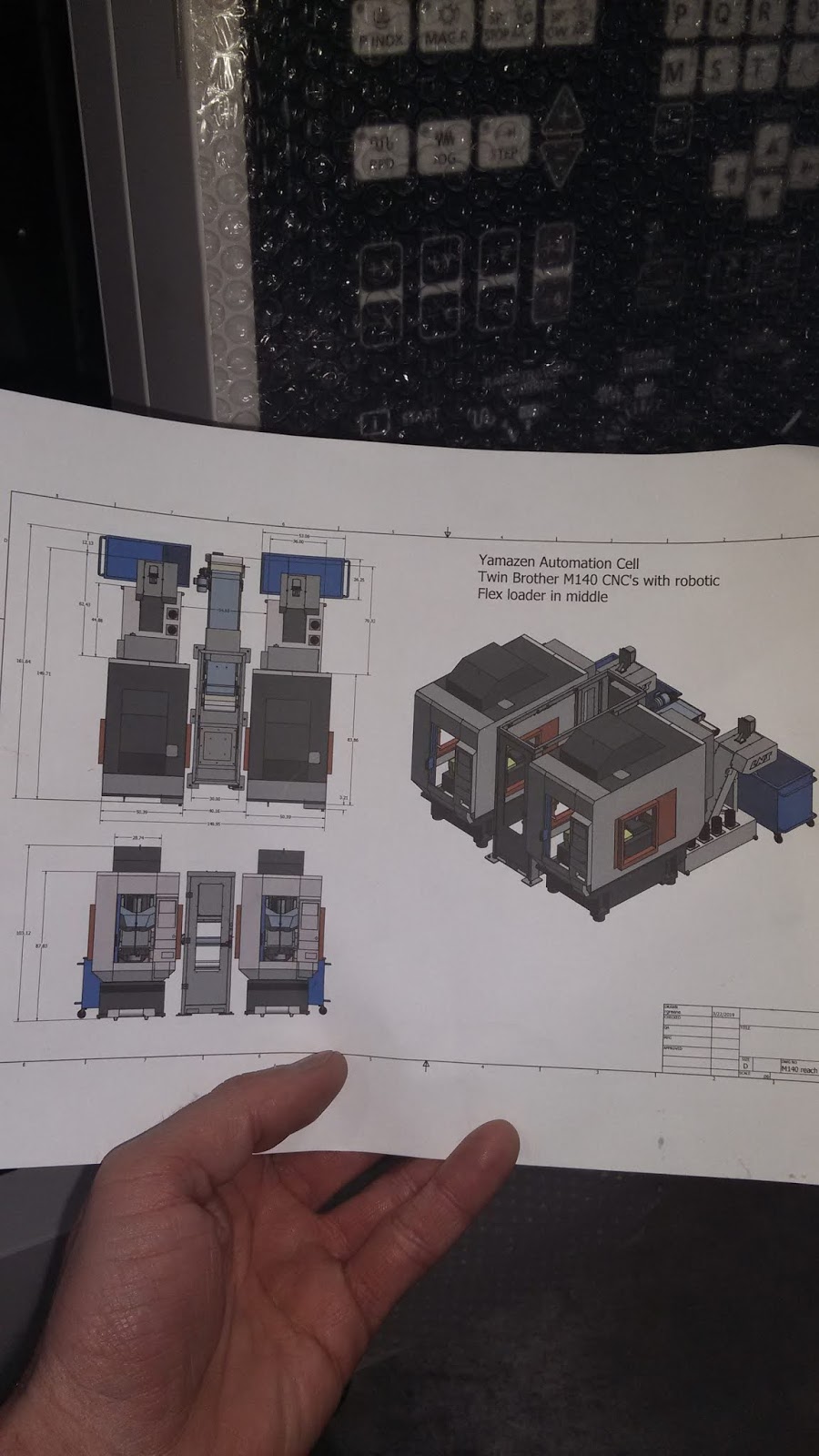

We got a few more customers on board and some purchase orders are coming in that overwhelm our capacity, plus we have a special project with Yamazen's new automation division for an in-house product that we support.

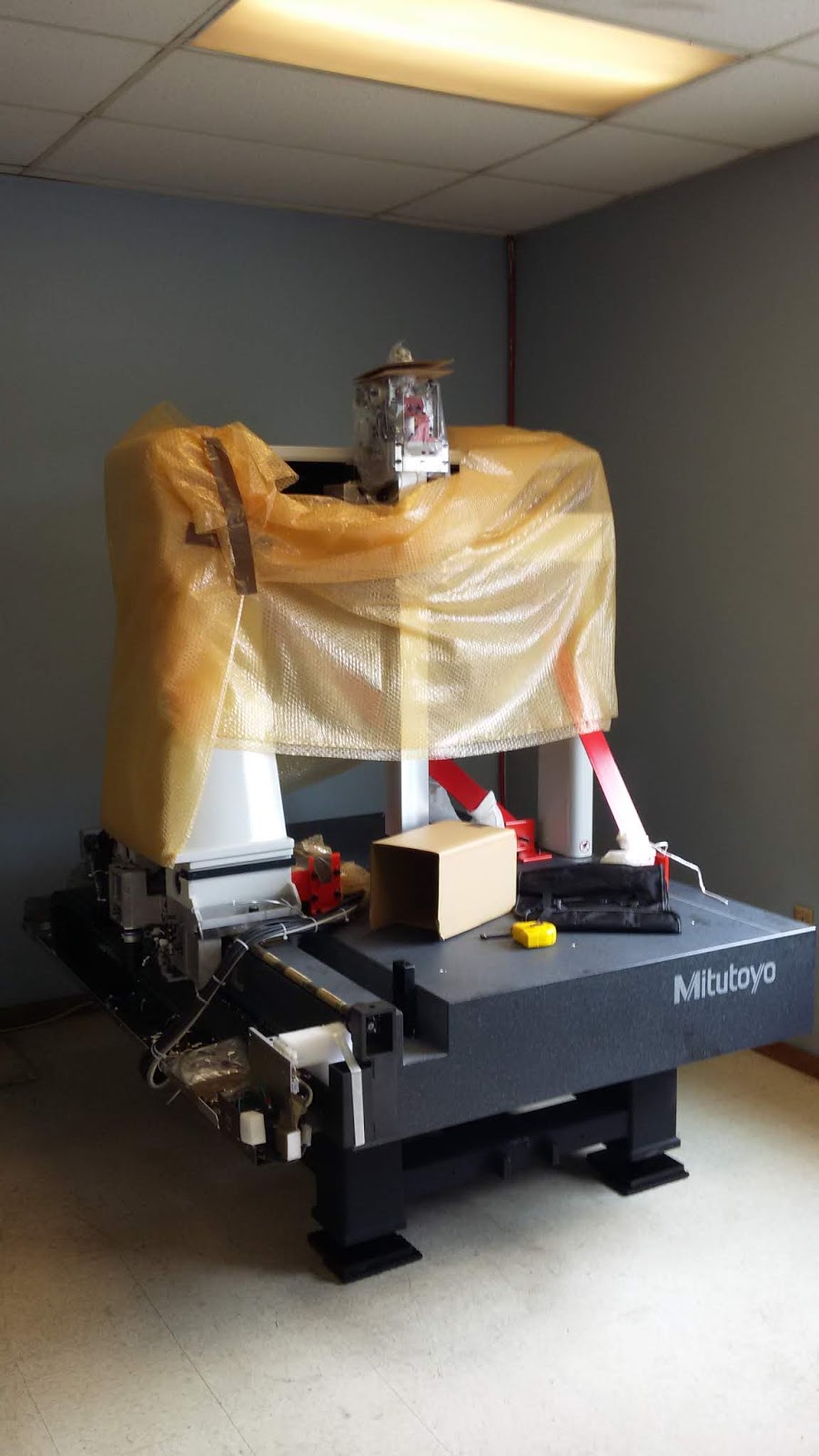

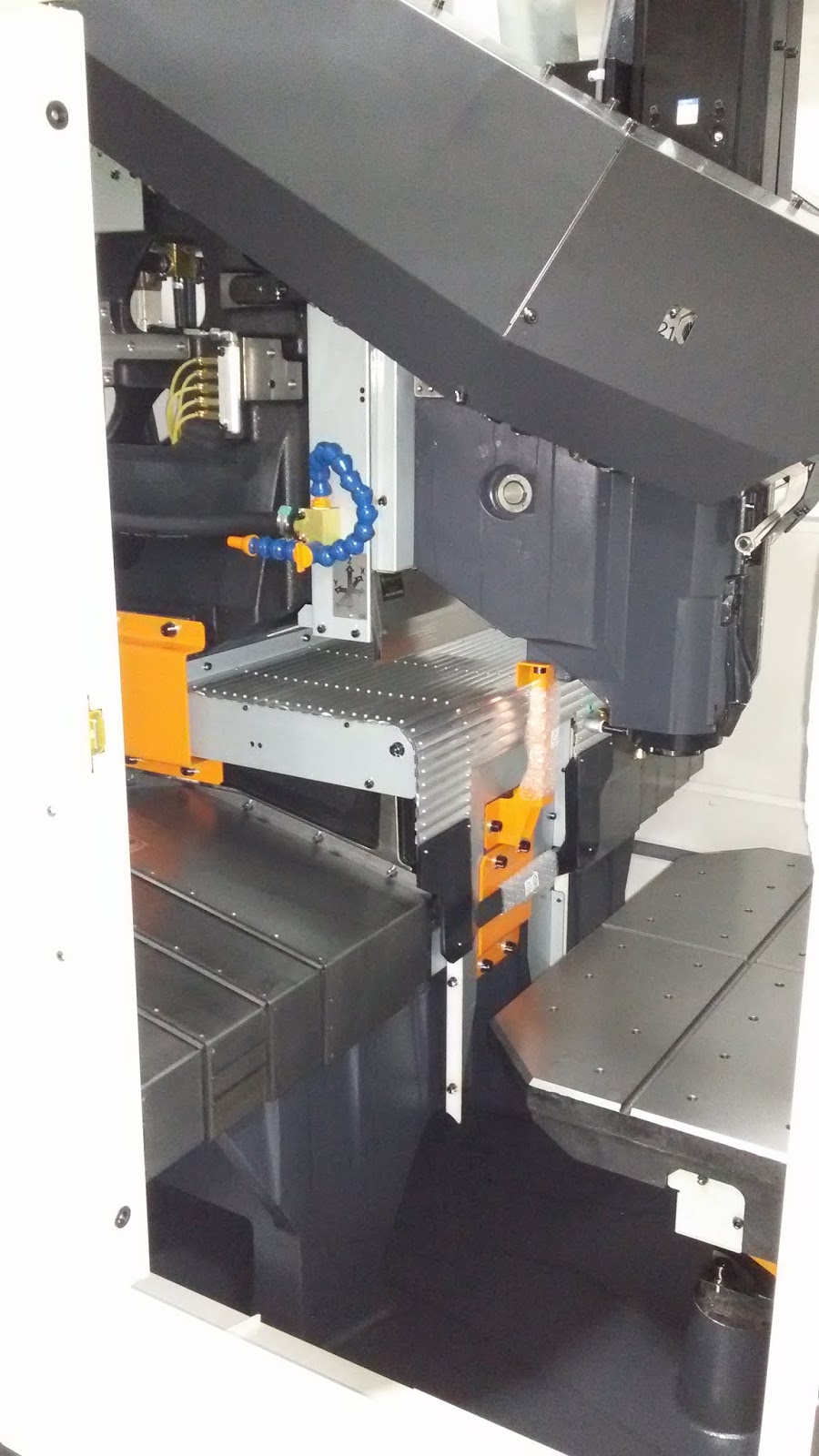

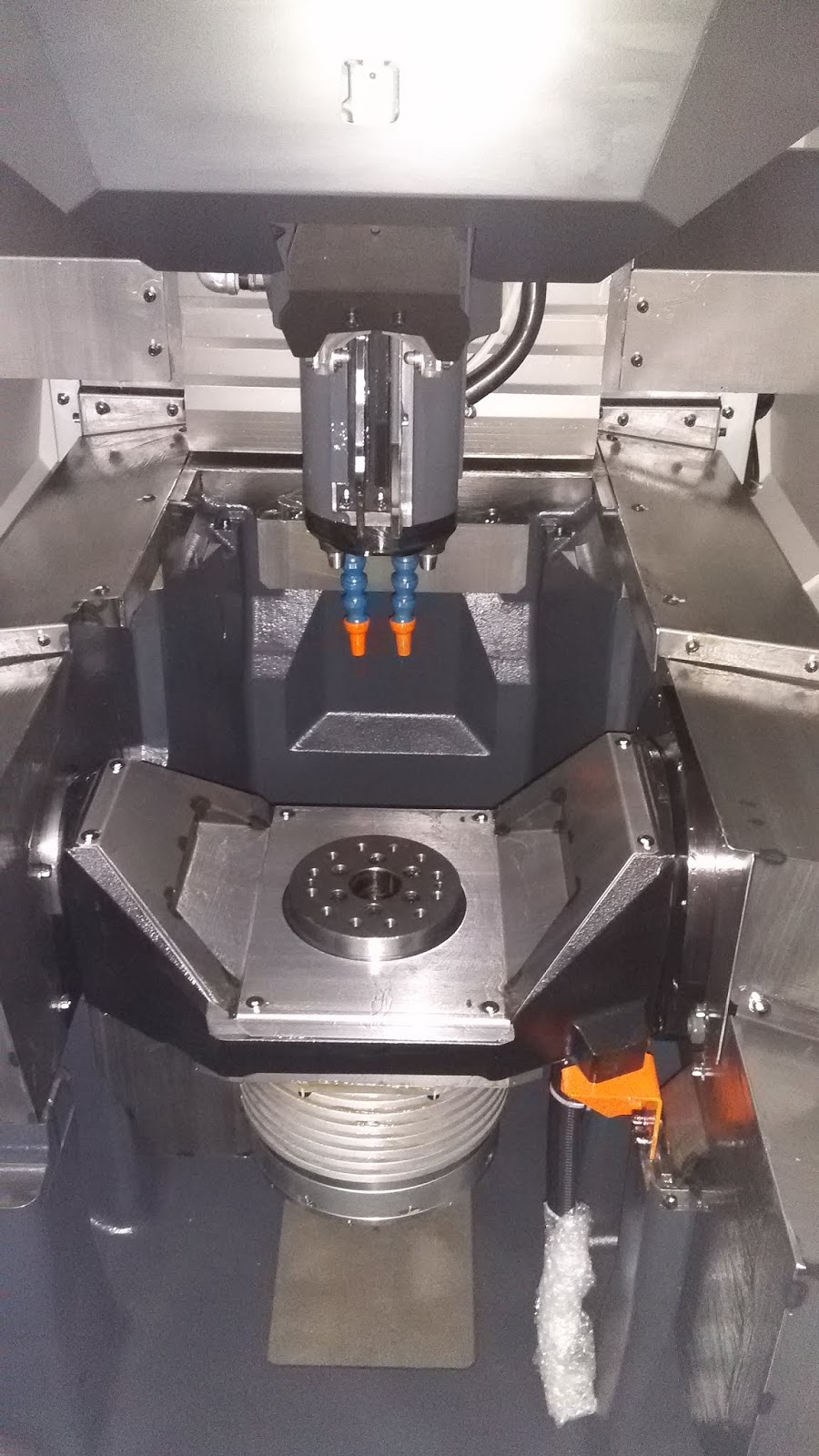

So... We just got an S1000X1 with the 10k High Torque and dual contact, an R650X1 with the same, and a pair of M140X2s that are getting paired up with a Nachi robot cell and conveyor load/unload system. We also got a Mitutoyo CMM as part of the package deal with Yamazen.

First we made some space! We also have another turning center coming in (next week?) and we're moving our other turning center as well.

We love seeing those big metal crates!

The R650X1

S1000X1

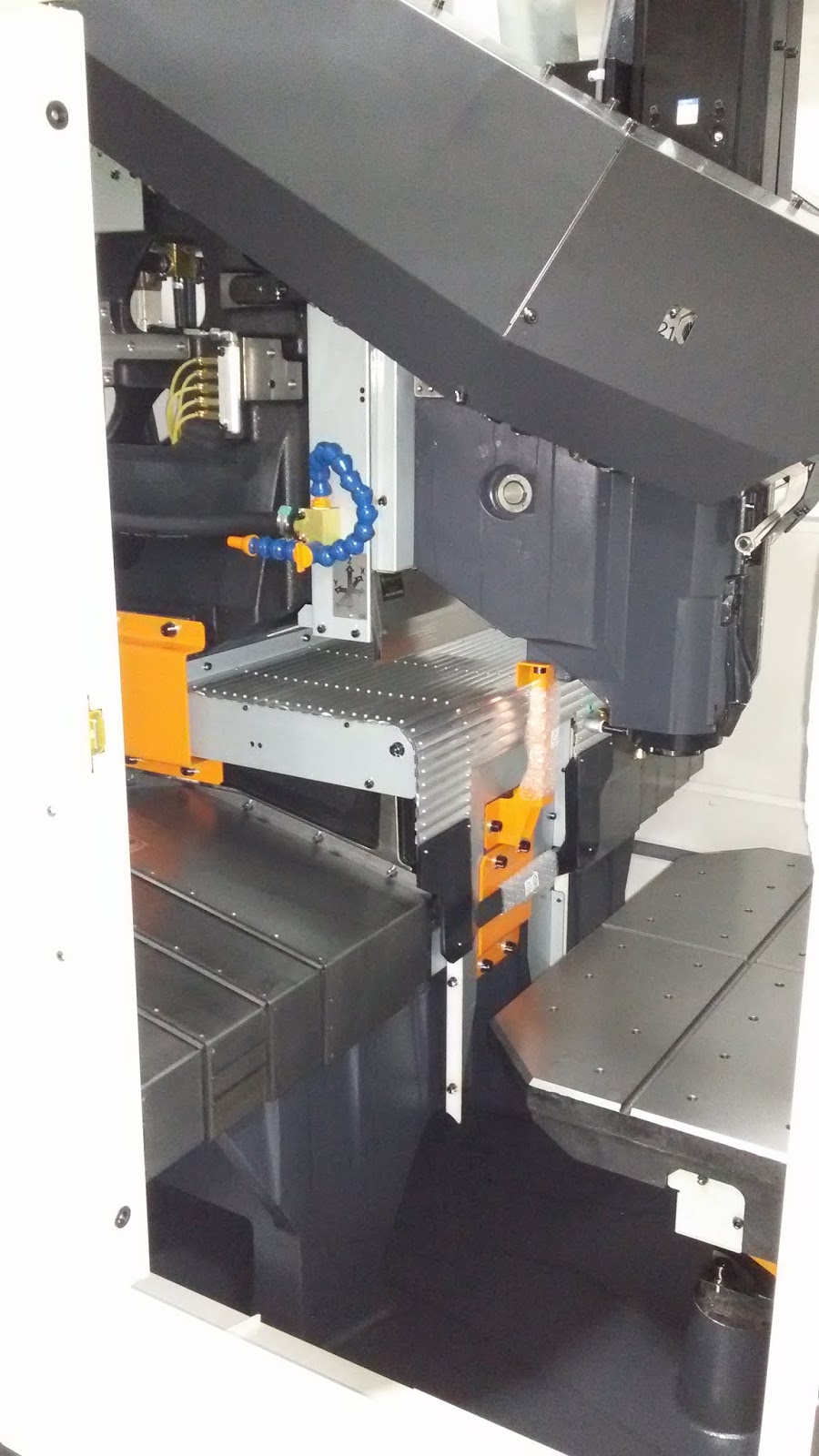

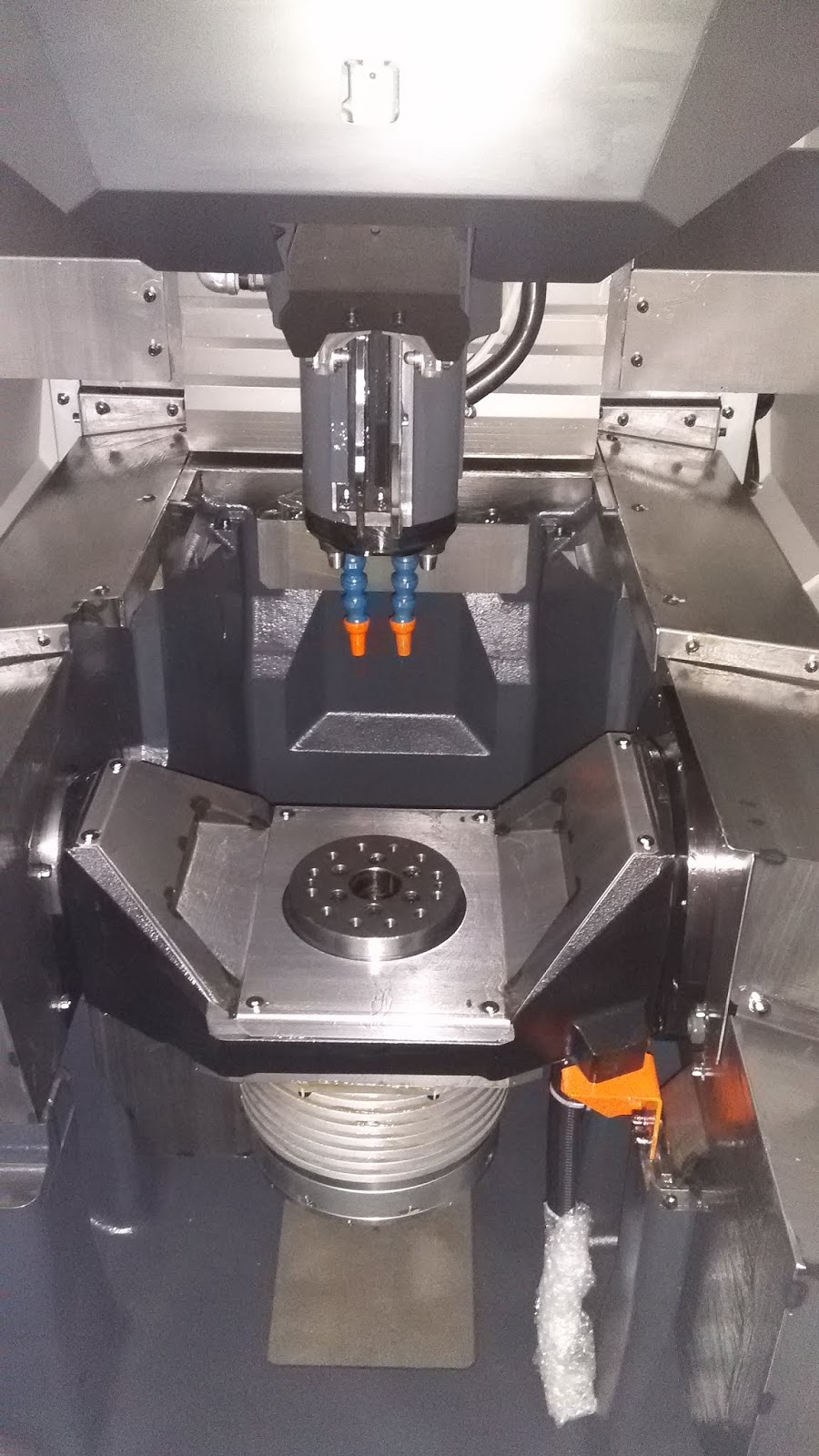

M140X2s

ROBOT CELL!

Pay no attention to the Mori; her days are numbered!

Mitutoyo CMM (500mm I think?)

Super excited to see some of these run. We have part quantities in the hundreds of thousands at first and we're looking at upwards of a half million for some business we're going after. Once we've proven out the first R650X1 we have planned for the capacity of tow more by year's end. Out turning centers our packed with work right now and I'm thinking we'll be adding another Swiss before the year's end as well.

We're gonna need a few more programmers I think!

So... We just got an S1000X1 with the 10k High Torque and dual contact, an R650X1 with the same, and a pair of M140X2s that are getting paired up with a Nachi robot cell and conveyor load/unload system. We also got a Mitutoyo CMM as part of the package deal with Yamazen.

First we made some space! We also have another turning center coming in (next week?) and we're moving our other turning center as well.

We love seeing those big metal crates!

The R650X1

S1000X1

M140X2s

ROBOT CELL!

Pay no attention to the Mori; her days are numbered!

Mitutoyo CMM (500mm I think?)

Super excited to see some of these run. We have part quantities in the hundreds of thousands at first and we're looking at upwards of a half million for some business we're going after. Once we've proven out the first R650X1 we have planned for the capacity of tow more by year's end. Out turning centers our packed with work right now and I'm thinking we'll be adding another Swiss before the year's end as well.

We're gonna need a few more programmers I think!

).

).