danpayneuk

Plastic

- Joined

- Feb 13, 2021

Hey guys

I am looking at purchasing a new vice ( Im in the UK so that's how we spell it )

)

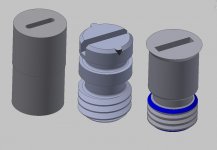

Narrowed it down to either Chick or Orange. I like the versality of the Orange more than the Chick, due to the orange being able to swap bewtween single and double station. Also means I could run two and know heights etc would all be the same.

However I like the system of the one lok single vice and that the fixed jaw is at the front.

Can the Orange vice be used with the fixed jaw at the front?

Any thought or personal opinions on either would be great. If you have used or have both then even better.

Thanks

I am looking at purchasing a new vice ( Im in the UK so that's how we spell it

)

)Narrowed it down to either Chick or Orange. I like the versality of the Orange more than the Chick, due to the orange being able to swap bewtween single and double station. Also means I could run two and know heights etc would all be the same.

However I like the system of the one lok single vice and that the fixed jaw is at the front.

Can the Orange vice be used with the fixed jaw at the front?

Any thought or personal opinions on either would be great. If you have used or have both then even better.

Thanks