Timberwerkz

Plastic

- Joined

- Jun 30, 2012

- Location

- Houston Tx

I'm running a Nakamura Super NTJX and am using the B-axis to make an ID groove. I keep getting a 0319 "The end point command is illegal in drilling cycle"alarm. The lovely alarm book expands on this to say "Although ^i or ^k travel distance is set to 0 in a multiple reptitive canned cutting-off cycle (G74 or G75), a value other than 0 is specified at U or W

Machine is a 2 spindle machine with lower turret and upper B-axis milling spindle. Groove is being cut on the right spindle

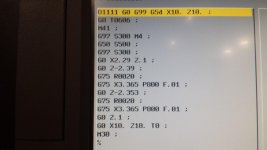

Program is

G0 Z-.2

X2.29

Z2.39

G75 R.002

G75 X3.365 P800 F.004

Z2.353

G75 R.002

G75 X3.365 P800 F.004

It alarms out before it starts the first groove at G75 R.02

Thanks in advance for help,

Chris

Machine is a 2 spindle machine with lower turret and upper B-axis milling spindle. Groove is being cut on the right spindle

Program is

G0 Z-.2

X2.29

Z2.39

G75 R.002

G75 X3.365 P800 F.004

Z2.353

G75 R.002

G75 X3.365 P800 F.004

It alarms out before it starts the first groove at G75 R.02

Thanks in advance for help,

Chris