sendithard

Plastic

- Joined

- May 18, 2021

I'm needing to write a simple contour path leaving .010" stock then a finishing pass for this class I'm in. I understand how to write the G41 cutter comp and how to properly turn it on and off with a G01 pre-move.

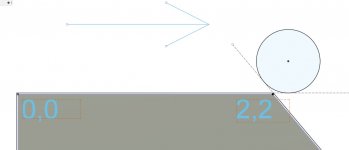

Below is a picture of the part. I read somewhere instead of entering D01 and pulling from the T01 diamter(radius) offset you can instead manually enter a P0.25 to reflect the radius of a 1/2" end mill.

This got me thinking if you can avoid doing trig to get the .010" offset outline of the part by entering in that additional .010" into the P value. So if I enter a P value of 0.26 will this effectively push the 1/2" cutter that extra .010" away from the part so I am left with that amount of stock? If this is the case, it would make handling the handwritten gcode much easier at non-perpendicular corners.

And just so I understand how the controller is working...to get the proper cutter placement in the 2nd photo...is it doing the necessary math to push this cutter tangent to the next line created by the next G01 location by means of some type of lookahead?

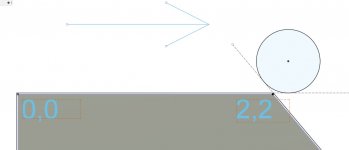

My next question relates to the above but I'm wondering if I instruct the cutter to round the corner of the part at 2,2 as seen in the 3rd photo will the G41 then do the proper round when I again use the P0.26 as seen in the 4th photo?

Thanks.

Below is a picture of the part. I read somewhere instead of entering D01 and pulling from the T01 diamter(radius) offset you can instead manually enter a P0.25 to reflect the radius of a 1/2" end mill.

This got me thinking if you can avoid doing trig to get the .010" offset outline of the part by entering in that additional .010" into the P value. So if I enter a P value of 0.26 will this effectively push the 1/2" cutter that extra .010" away from the part so I am left with that amount of stock? If this is the case, it would make handling the handwritten gcode much easier at non-perpendicular corners.

And just so I understand how the controller is working...to get the proper cutter placement in the 2nd photo...is it doing the necessary math to push this cutter tangent to the next line created by the next G01 location by means of some type of lookahead?

My next question relates to the above but I'm wondering if I instruct the cutter to round the corner of the part at 2,2 as seen in the 3rd photo will the G41 then do the proper round when I again use the P0.26 as seen in the 4th photo?

Thanks.