zirconium

Plastic

- Joined

- Dec 30, 2007

- Location

- Bogotá Colombia

First at all: Happy New Year for all of You!

Happy New Year for all of You!

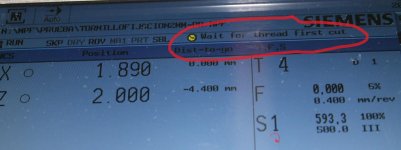

I have a trouble with sinumerik 808D control (mounted on a L28 cnc optimum lathe machine), when programming threading cycles (Cycle 99 or G33) the tool remains quiet no operation is performing and a "wait for first thread cut" line is displayed. This kind of messages have no mention in manuals of 808D. I keep the outmost care in programming parameters for cycle99 and with g33 but I can´t solve this question so I ask for help.

Facing, Profiling and Turning cycles have no problems.

Thank You.

Happy New Year for all of You!

Happy New Year for all of You!I have a trouble with sinumerik 808D control (mounted on a L28 cnc optimum lathe machine), when programming threading cycles (Cycle 99 or G33) the tool remains quiet no operation is performing and a "wait for first thread cut" line is displayed. This kind of messages have no mention in manuals of 808D. I keep the outmost care in programming parameters for cycle99 and with g33 but I can´t solve this question so I ask for help.

Facing, Profiling and Turning cycles have no problems.

Thank You.