Houndogforever

Hot Rolled

- Joined

- Oct 20, 2015

- Location

- Boring

Yeah, I just said that.

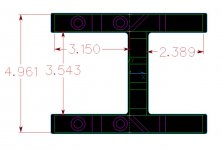

I have a part, measures about 4x7. It gets milled into a layed down H shape. I currently do it in my trusty Fadal 3016, but I was wondering.

It needs to be milled .92 deep and each leg and cross beam of the H measures 20mm (.787)wide.

I have done it a few times on my Fadal, using a 1/2" Emco 5 flute, full axial depth and a .075 radial. I believe that runs about 470 SFM at .0054 ipt.

I don't reckon the little speedio BT30 isn't going to take a .075 radial cut.

The inside corners wont jam up the endmill as they are OS at this stage. I come back in with 1/4 and 3/8 tools later.

So, P20 steel, S700X1 Speedio 16K and a lot of material to be peeled off.

What would you guys run this at?

Thanks

I have a part, measures about 4x7. It gets milled into a layed down H shape. I currently do it in my trusty Fadal 3016, but I was wondering.

It needs to be milled .92 deep and each leg and cross beam of the H measures 20mm (.787)wide.

I have done it a few times on my Fadal, using a 1/2" Emco 5 flute, full axial depth and a .075 radial. I believe that runs about 470 SFM at .0054 ipt.

I don't reckon the little speedio BT30 isn't going to take a .075 radial cut.

The inside corners wont jam up the endmill as they are OS at this stage. I come back in with 1/4 and 3/8 tools later.

So, P20 steel, S700X1 Speedio 16K and a lot of material to be peeled off.

What would you guys run this at?

Thanks