What is a good strategy for weight reduction of an aluminium plate, 25mm thick x 750mm dia.

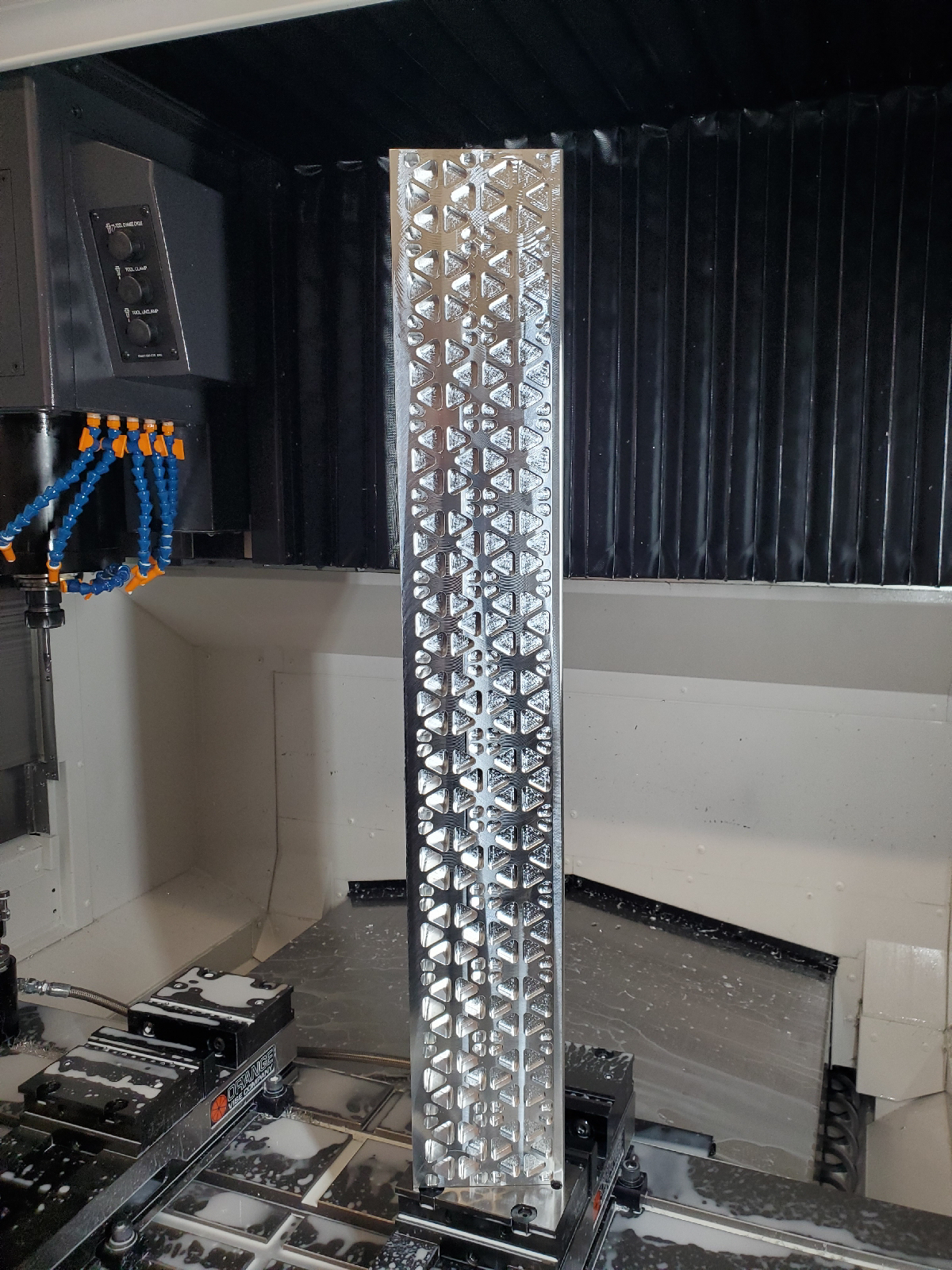

Have to make the plate shown in the image lighter and I believe machining diamond shapes out of it is a good way forward. Could anyone point me in the right direction for good engineering practices?

It's sitting on a Weiss indexer and doesn't have much weight on top of it.

Have to make the plate shown in the image lighter and I believe machining diamond shapes out of it is a good way forward. Could anyone point me in the right direction for good engineering practices?

It's sitting on a Weiss indexer and doesn't have much weight on top of it.