New to the forum and I've found this site very useful for years. First off I'm not a programmer by trade but have been thrown into the role since our engineers at my workplace don't contribute much in this aspect of my job in Maintenance and we don't have a cam program for our cnc lathes. We have a pretty extensive set of duties here including full machining, electrical, repair, building etc. You name it we have to have some knowledge in it.

I've read every post here concerning G76 code programming for my machine which has a Fanuc 21i-TB control. I'll list the program and what it does. I'm trying to turn 1/2-20 threads and I have self taught myself on this machine so far. It's done everything I've programed with other repetitive canned cycles but just won't thread on this portion . Here's what I've got in the part of the program where it stops on 2nd line of G76 and just sits there doing nothing:

N340 T0909

N350 G97 S800 M04

N360 G0 X.550

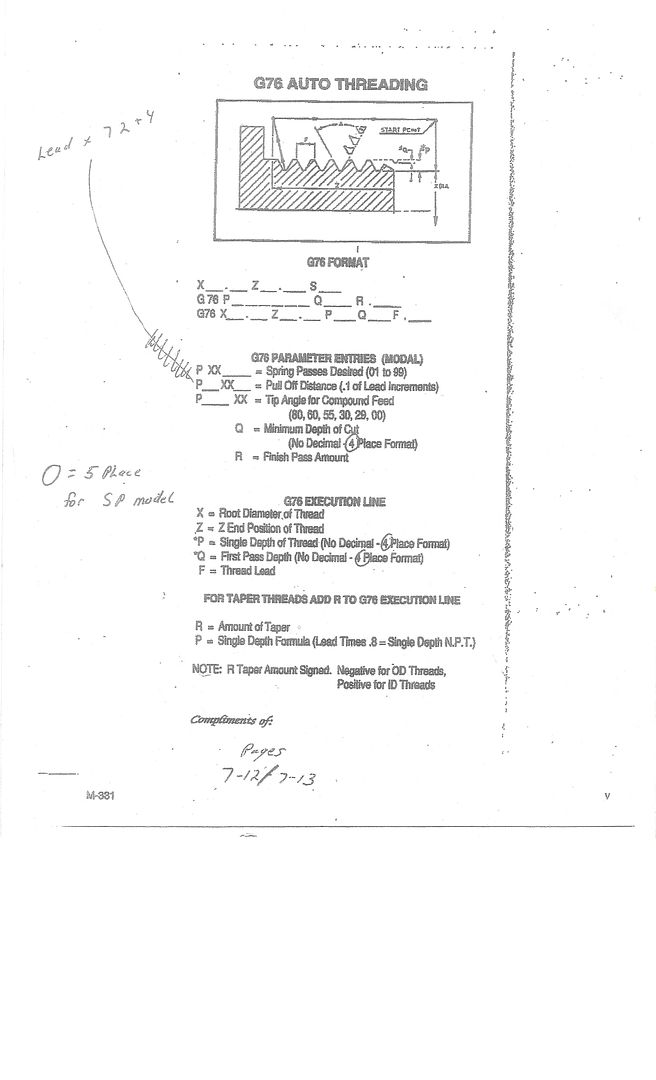

N370 G76 P020060 Q0050 R.0005

N380 G76 X.404 Z-.90 P0100 Q0472 F.0769

N390 G1X5.0 F.150

N400 M30

It just seems like the machine is waiting for more information as it sits at the starting point of where the threading starts. In running the simulation it appears to only run 2 passes in the threading portion but it does show it threading. Everything else in this program works fine.

Any input or help would be greatly appreciated as I've exhausted every means. Thanks again for this great site!

JT

I've read every post here concerning G76 code programming for my machine which has a Fanuc 21i-TB control. I'll list the program and what it does. I'm trying to turn 1/2-20 threads and I have self taught myself on this machine so far. It's done everything I've programed with other repetitive canned cycles but just won't thread on this portion . Here's what I've got in the part of the program where it stops on 2nd line of G76 and just sits there doing nothing:

N340 T0909

N350 G97 S800 M04

N360 G0 X.550

N370 G76 P020060 Q0050 R.0005

N380 G76 X.404 Z-.90 P0100 Q0472 F.0769

N390 G1X5.0 F.150

N400 M30

It just seems like the machine is waiting for more information as it sits at the starting point of where the threading starts. In running the simulation it appears to only run 2 passes in the threading portion but it does show it threading. Everything else in this program works fine.

Any input or help would be greatly appreciated as I've exhausted every means. Thanks again for this great site!

JT