ToolCat

Aluminum

- Joined

- Dec 20, 2005

- Location

- Kearney, NE

Trying to add a touch probe to a Makino rcm55 - fanuc 0M.

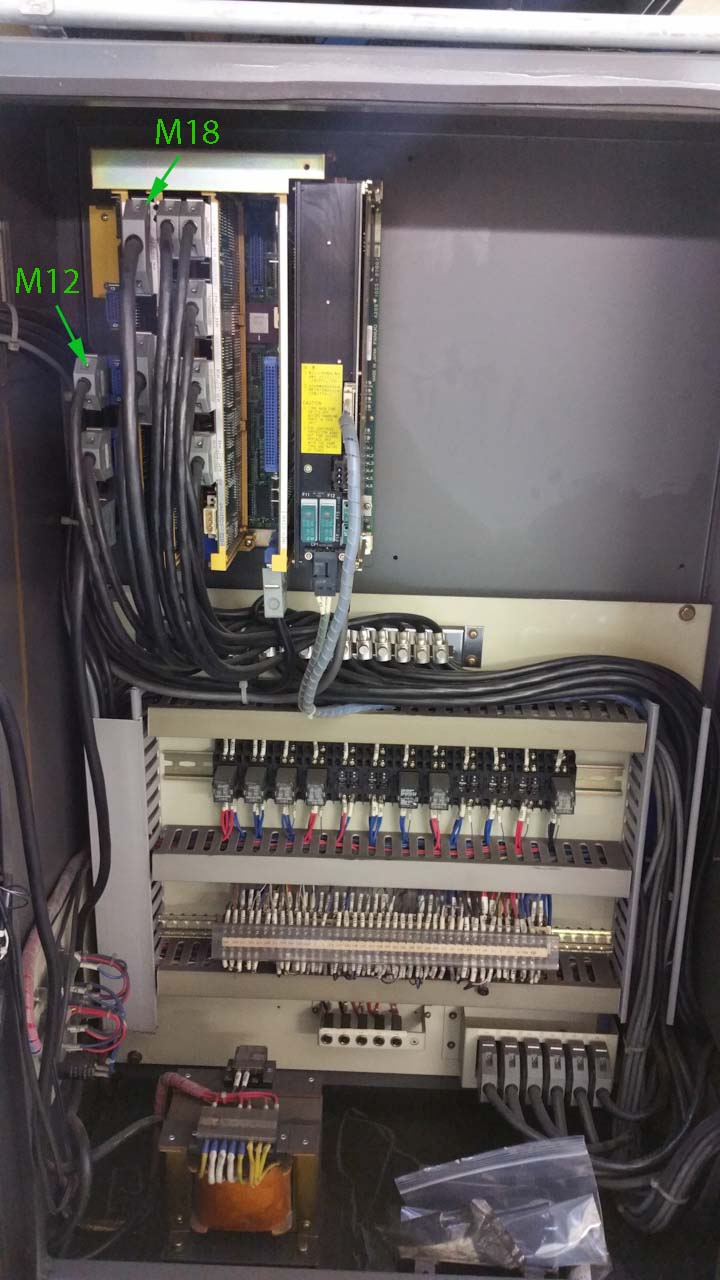

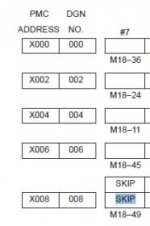

From what I read it can be done at pin 49 on the M18 connector. I have located M18, and it has a cable connected to it. I am trying to trace where it goes to find a place that I can get to pin 49?

Or I read the skip signal can be done with a high speed interface through M12 pin 14. Same problem though. Where does the wire lead that I can get to pin 14 of M12?

From what I read it can be done at pin 49 on the M18 connector. I have located M18, and it has a cable connected to it. I am trying to trace where it goes to find a place that I can get to pin 49?

Or I read the skip signal can be done with a high speed interface through M12 pin 14. Same problem though. Where does the wire lead that I can get to pin 14 of M12?