How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turning between centers

- Thread starter shahargut

- Start date

- Replies 35

- Views 5,641

plastikdreams

Diamond

- Joined

- May 31, 2011

- Location

- upstate nj

You need a lathe dog. They can be bought or made.

KristianSilva

Aluminum

- Joined

- Nov 26, 2016

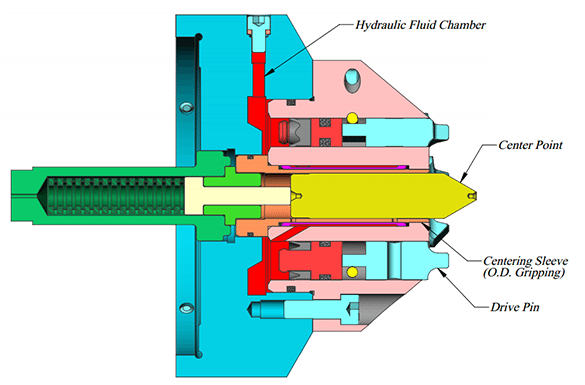

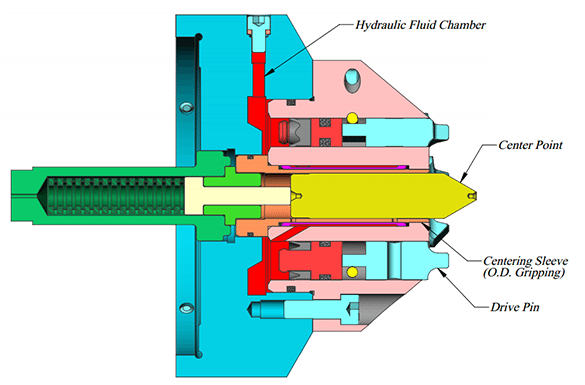

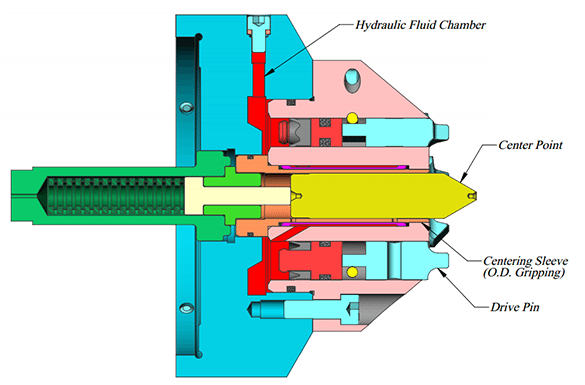

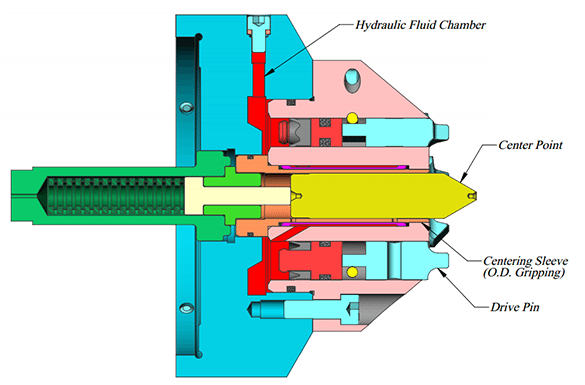

face driver

M.B. Naegle

Diamond

- Joined

- Feb 7, 2011

- Location

- Conroe, TX USA

Coadster32

Aluminum

- Joined

- May 4, 2011

- Location

- Milford, Ct

As stated...Lathe Dog or Face Driver are the most common methods. Sometimes if you're doing a light skim cut, just add a little more tailstock pressure, and then you don't need a driver.

pgmrmike

Hot Rolled

- Joined

- Jun 24, 2010

- Location

- Plantersville, TX

You need a lathe dog. They can be bought or made.

face driver

As stated...Lathe Dog or Face Driver are the most common methods. Sometimes if you're doing a light skim cut, just add a little more tailstock pressure, and then you don't need a driver.

Yep. Small diameter and fairly light cuts, tailstock pressure works. Just dont get too aggressive with the pressure, too much on a small dia part can bend it.

Jashley73

Titanium

- Joined

- Jan 24, 2013

- Location

- Louisville, KY

Face driver if possible. Lathe dogs work well, but if runout is super-critical, the unequal mass of a lathe dog can cause strange things, and this gets worse the higher the rpm.

If we're talking engine lathe speeds, then you're probably OK with a lathe dog, but if the runout & circularity is that critical, then stay as close to a face-driver setup [read: radially symmetrical, & dynamically balanced] as possible.

If we're talking engine lathe speeds, then you're probably OK with a lathe dog, but if the runout & circularity is that critical, then stay as close to a face-driver setup [read: radially symmetrical, & dynamically balanced] as possible.

Gobo

Titanium

- Joined

- Jun 4, 2013

- Location

- Oregon, USA

Pretty vague. A wee bit more detail would aid your cause.

thermite

Diamond

- Joined

- Sep 21, 2011

That applies only to the ancient ones, and they happen to be better balanced, dynamically than first appears. Lathes were slower, back in their day. It just wasn't a problem, nor need it be, now.Face driver if possible. Lathe dogs work well, but if runout is super-critical, the unequal mass of a lathe dog can cause strange things, and this gets worse the higher the rpm.

In any case, it isn't at all hard to shop fab a VERY well balanced one.

Two near-as-dammit identical bars, each with a Vee cutout arranged for equal length of bypass, opposite direction. Equal mass fasteners for clamping. That implementation must be easily 200 years old in use. A small "set" of forged loop and bent-tail were just handier.

You want a Rzeppa joint for TS set-over tapers? Have at it.

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

That applies only to the ancient ones, and they happen to be better balanced, dynamically than first appears. Lathes were slower, back in their day. It just wasn't a problem, nor need it be, now.

In any case, it isn't at all hard to shop fab a VERY well balanced one.

Two near-as-dammit identical bars, each with a Vee cutout arranged for equal length of bypass, opposite direction. Equal mass fasteners for clamping. That implementation must be easily 200 years old in use. A small "set" of forged loop and bent-tail were just handier.

You want a Rzeppa joint for TS set-over tapers? Have at it.

You can balance a lathe dog I guess, but they still prevent turning the entire OD in one setup.

Face driver is better in every way. Especially the hydraulic ones that don't care about the precision of the face...

thermite

Diamond

- Joined

- Sep 21, 2011

You can balance a lathe dog I guess, but they still prevent turning the entire OD in one setup.

Face driver is better in every way. Especially the hydraulic ones that don't care about the precision of the face...

Must be a stock item? Show us a link. Locomotive axles to carburretor metering rods, please.

Otherwise, I'll stick with women for hydraulic "face driving", thanks!

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

Must be a stock item? Show us a link. Locomotive axles to carburretor metering rods, please.

Otherwise, I'll stick with women for hydraulic "face driving", thanks!

So, the basic principle is the driving dogs are actually hydraulic pistons which all share a common reservoir, and therefore conform to the profile of the face with equal pressure. I think Sandvik Kosta were the first to make such, but they are commonly available from a number of manufacturers now. They can be had in surprisingly small diameters.

thermite

Diamond

- Joined

- Sep 21, 2011

So, the basic principle is the driving dogs are actually hydraulic pistons which all share a common reservoir, and therefore conform to the profile of the face with equal pressure. I think Sandvik Kosta were the first to make such, but they are commonly available from a number of manufacturers now. They can be had in surprisingly small diameters.

Thanks for that, Gregor.

I'm sure it will benefit "someone". I just don't happen to be he, this incarnation. At least not until I get another two Delta-Wye transformers bought and can get back to serious workholder hoarding again..

pgmrmike

Hot Rolled

- Joined

- Jun 24, 2010

- Location

- Plantersville, TX

So, the basic principle is the driving dogs are actually hydraulic pistons which all share a common reservoir, and therefore conform to the profile of the face with equal pressure. I think Sandvik Kosta were the first to make such, but they are commonly available from a number of manufacturers now. They can be had in surprisingly small diameters.

Very interesting. Have never seen that type before. Thanks

Ox

Diamond

- Joined

- Aug 27, 2002

- Location

- Northwest Ohio

So, the basic principle is the driving dogs are actually hydraulic pistons which all share a common reservoir, and therefore conform to the profile of the face with equal pressure. I think Sandvik Kosta were the first to make such, but they are commonly available from a number of manufacturers now. They can be had in surprisingly small diameters.

Well if that don't beat all!

That is exactly what I envissioned from your previous description, but I really ??? the small chambers that it would have to be... ???

The Hydramax vise jaws have much more biggerer piston sizes, but apparently this works, and if so - would be a God-send for castings and such!

---------------------

Think Snow Eh!

Ox

I wonder if the "blades" or Drive pins (per the model) are a consumable item. I would automatically think and assume; YES, but how easy/cheap/accessible are they to replace?

R

Yes, I have seen them replaced IIRC the operator was able to replace them.

Now do any here actually think that the OP , who is asking about what is likely his first attempt at between center turning, is going to spring for a hydraulic compensated face driver?

Get real!

Just getting both a drive plate and a center in the lathe at the same time is going to be an issue.

Turning at "dog speed" is never going to cause a problem, that is why they invented carbon steel tool bits.

Jeesh!

Get real!

Just getting both a drive plate and a center in the lathe at the same time is going to be an issue.

Turning at "dog speed" is never going to cause a problem, that is why they invented carbon steel tool bits.

Jeesh!

Similar threads

- Replies

- 2

- Views

- 284

- Replies

- 4

- Views

- 291

- Replies

- 15

- Views

- 463