Rick Finsta

Stainless

- Joined

- Sep 27, 2017

So, my 2005 Sharp SV-2412 with FANUC 0i-Mate MB had this idiotic thing where to access the memory card I needed to shut off power and open the electrical mains cabinet. So I looked and looked for a PCMCIA/PC Card or Compact Flash ribbon cable extender, and the only outfit in the world to make anything like this is a German company, ES&S. It was just over $300 to my door for two of the cards and mounting chassis. I'll save that much in short order just in the time for having to shut everything down.

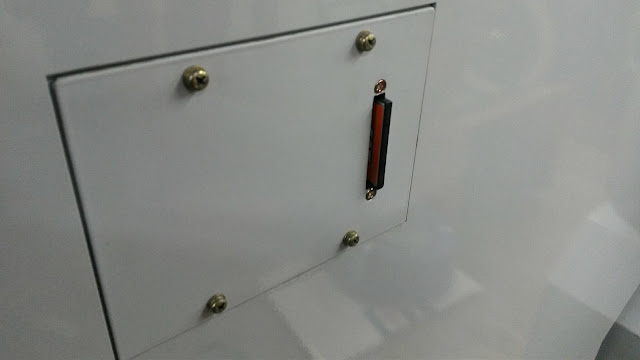

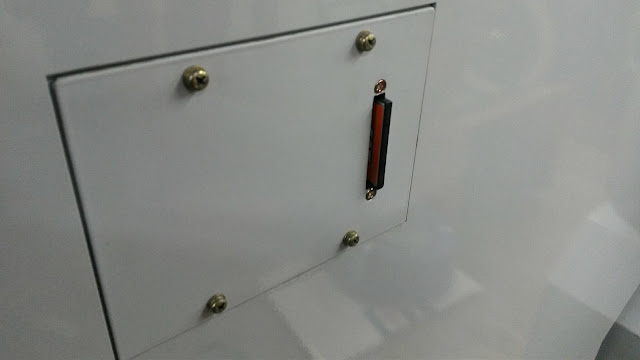

The Sharp had a panel that fit this modification perfectly, almost like they intended to do something like this...? This made it easy to pull the panel and mill the slot out on my Bridgeport. Just think, transistors and integrated circuits were still decades off when my '46 was made, and here she is still cutting well into the next century!

This is the 600mm version, which is the longest they make and you can open the door easily enough to access the card side. I'm using a Transcend brand PCMCIA to Compact Flash adapter, and no issues so far.

The card sticks out just enough to comfortably grasp it and remove it. I wish they made this with an ejector button, but I'll take what I can get!

And proof that it works! I can now just pull the card and swap it out without having to shut everything down. I am happy!

The Sharp had a panel that fit this modification perfectly, almost like they intended to do something like this...? This made it easy to pull the panel and mill the slot out on my Bridgeport. Just think, transistors and integrated circuits were still decades off when my '46 was made, and here she is still cutting well into the next century!

This is the 600mm version, which is the longest they make and you can open the door easily enough to access the card side. I'm using a Transcend brand PCMCIA to Compact Flash adapter, and no issues so far.

The card sticks out just enough to comfortably grasp it and remove it. I wish they made this with an ejector button, but I'll take what I can get!

And proof that it works! I can now just pull the card and swap it out without having to shut everything down. I am happy!