DavidScott

Diamond

- Joined

- Jul 11, 2012

- Location

- Washington

Well I had a nasty surprise when doing my Friday wash down. The telescoping Y axis way cover had one segment that was very skewed with a big gap between the top wiper and adjacent segment with one side bent out at the bottom  . The good news is there is no real damage to the metal but I need to procure some plastic and rubber parts to fix it. Luckily, I hope, it was made by Henning so from their website it looks like I can get the parts, at least for the Y axis covers. Both the X and Z axis covers look original and the X covers need some parts too. The problem started with worn plastic parts, some missing, that allowed the seals to let some chips in, which built up in the bottom of the sides, which got in the way when the table was moved close to the column. Henning has a nice repair manual online that was a wealth of info when I needed it on Saturday. Here is the link http://www.hennig-inc.com/fileadmin/user_upload/PDFs/Assembly_Instructions/TSC/MTSA_E_1306.pdf . In the manual it states that occasional inspection and cleaning to avoid this is needed. Below are a few photos showing what I have so far.

. The good news is there is no real damage to the metal but I need to procure some plastic and rubber parts to fix it. Luckily, I hope, it was made by Henning so from their website it looks like I can get the parts, at least for the Y axis covers. Both the X and Z axis covers look original and the X covers need some parts too. The problem started with worn plastic parts, some missing, that allowed the seals to let some chips in, which built up in the bottom of the sides, which got in the way when the table was moved close to the column. Henning has a nice repair manual online that was a wealth of info when I needed it on Saturday. Here is the link http://www.hennig-inc.com/fileadmin/user_upload/PDFs/Assembly_Instructions/TSC/MTSA_E_1306.pdf . In the manual it states that occasional inspection and cleaning to avoid this is needed. Below are a few photos showing what I have so far.

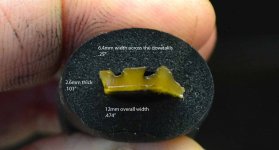

It doesn't look too bad but it doesn't take very many chips in the wrong spot to cause some expensive problems. The photo of chips is what came off the covers. I have already hammered the dents out and nudged the sides back in so the seals work. Once I get the parts and the covers assembled correctly I will sand them smooth.

Since way covers are a common issue for us all I figured I would document my repair. If I had waited a few more days I think I would be sending it all off to Henning for them to do it. As Richard King posted a few days ago how often do you pull off the way covers and make sure all is well, including the lube ports. I think most big problems start with minor failures.

The "help" part may come later if I can't find all the parts I need.

. The good news is there is no real damage to the metal but I need to procure some plastic and rubber parts to fix it. Luckily, I hope, it was made by Henning so from their website it looks like I can get the parts, at least for the Y axis covers. Both the X and Z axis covers look original and the X covers need some parts too. The problem started with worn plastic parts, some missing, that allowed the seals to let some chips in, which built up in the bottom of the sides, which got in the way when the table was moved close to the column. Henning has a nice repair manual online that was a wealth of info when I needed it on Saturday. Here is the link http://www.hennig-inc.com/fileadmin/user_upload/PDFs/Assembly_Instructions/TSC/MTSA_E_1306.pdf . In the manual it states that occasional inspection and cleaning to avoid this is needed. Below are a few photos showing what I have so far.

. The good news is there is no real damage to the metal but I need to procure some plastic and rubber parts to fix it. Luckily, I hope, it was made by Henning so from their website it looks like I can get the parts, at least for the Y axis covers. Both the X and Z axis covers look original and the X covers need some parts too. The problem started with worn plastic parts, some missing, that allowed the seals to let some chips in, which built up in the bottom of the sides, which got in the way when the table was moved close to the column. Henning has a nice repair manual online that was a wealth of info when I needed it on Saturday. Here is the link http://www.hennig-inc.com/fileadmin/user_upload/PDFs/Assembly_Instructions/TSC/MTSA_E_1306.pdf . In the manual it states that occasional inspection and cleaning to avoid this is needed. Below are a few photos showing what I have so far.

It doesn't look too bad but it doesn't take very many chips in the wrong spot to cause some expensive problems. The photo of chips is what came off the covers. I have already hammered the dents out and nudged the sides back in so the seals work. Once I get the parts and the covers assembled correctly I will sand them smooth.

Since way covers are a common issue for us all I figured I would document my repair. If I had waited a few more days I think I would be sending it all off to Henning for them to do it. As Richard King posted a few days ago how often do you pull off the way covers and make sure all is well, including the lube ports. I think most big problems start with minor failures.

The "help" part may come later if I can't find all the parts I need.