G00 Proto

Hot Rolled

- Joined

- Feb 18, 2013

- Location

- Dirkdirkistan, ID

I was following a machining group on Facebook, and realized that the quality of content here was much higher (and more civilized). I think it is simply a function of how many year the members have been in this profession. I thought it would be interesting to put some data behind that assessment…

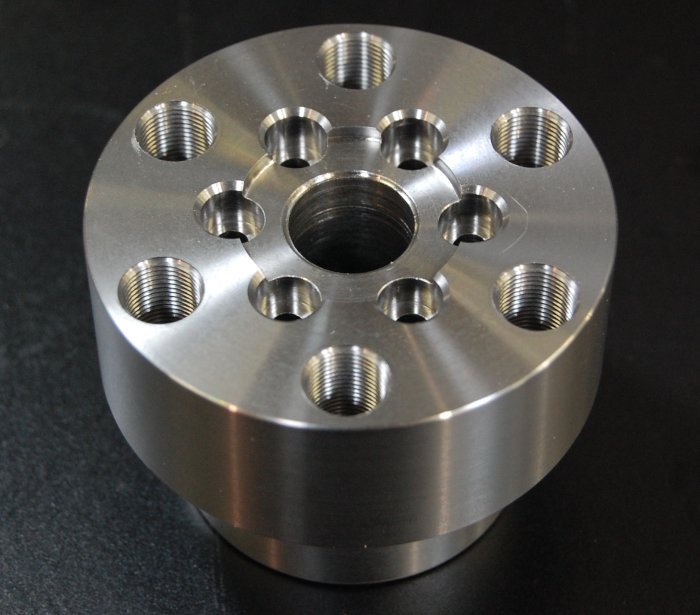

My first real parts were high pressure vessels turned out of 5" diameter 316 SS back in graduate school in 1996 (before I decided to follow my blue collar dream). I machined them on an archaic Logan Lathe and did the milling on a genuine Bridgeport with a rotary table. It was all downhill from there.

My first real parts were high pressure vessels turned out of 5" diameter 316 SS back in graduate school in 1996 (before I decided to follow my blue collar dream). I machined them on an archaic Logan Lathe and did the milling on a genuine Bridgeport with a rotary table. It was all downhill from there.

I thought reaming was some cleanup thing or something and I used the same size drill haha.

I thought reaming was some cleanup thing or something and I used the same size drill haha. (off center, not consistent, non concentric chamfers, etc). I made alot of tools when I started- parallels, angles, grinding vises, V blocks, etc. I have about half of them still I would guess. That was many moons ago when I was single and didn't mid staying after work to do stuff... times have changed! I can now buy (and even re-work if necessary) cheapie china brand stuff for less than I could buy the material, not to mention the labor...

(off center, not consistent, non concentric chamfers, etc). I made alot of tools when I started- parallels, angles, grinding vises, V blocks, etc. I have about half of them still I would guess. That was many moons ago when I was single and didn't mid staying after work to do stuff... times have changed! I can now buy (and even re-work if necessary) cheapie china brand stuff for less than I could buy the material, not to mention the labor...