I have an Abene VHF3 circa 1964 with leaking spindle oil seal

A few years ago, when I acquired the machine, I contacted Fredrik Yman at Abene AB and he forwarded me a parts list/drawing set for my machine. Abene are now out of business (bankrupt in 2020) and the new owner (Vemu AB)have been unresponsive to my enquiries. There's very little info available on these machines...

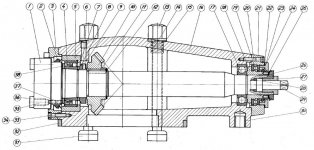

302.1xx spindle (believed to be my 1964 year model)

According to that documentation, it is equipped with spindle assembly with part number series 302.1xx and a bearing arrangement consisting of double row cylindrical roller bearing (I believe with tapered bore similar to SKF NN3010K) at the business end, and a single row angular contact ball bearing and thrust ball bearing at rear end (seems redundant....more to follow)

I'm currently trying to disassemble the spindle to fix the leaking oil seal and I'm looking for some enlightenment !!

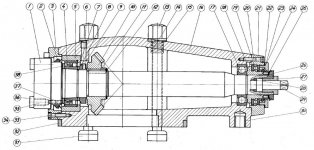

Firstly, the rear bearings are actually SKF 6207 (a regular deep groove ball bearing, not an angular contact bearing as the drawing above suggests), and a SKF 51110 thrust ball bearing. A slightly later spindle model 302.2xx shows the bearing as a regular deep groove ball bearing, consistent with that which I have found. It's drawing section is shown below (and is much clearer in its detail to the original 302.1xx drawing above. (note there's a slightly different numbering of the components).

302.2xx spindle (later year model)

With respect to disassembly, (and I've seen cwilcox's thread previously) I'm very nervous..

Abene Spindle Disassembly - Experience Requested

Referring to the drawing 302.2xx, I've removed all of the tail end components (18-29) except the deep groove ball bearing (17), and moved the circlip(12) which retains the bevel gear(10) toward the rear end of the spindle. It would now seem a simple matter of sliding the bevel gear along the spindle to allow the spindle to be pressed out trough its housing, the front roller bearing(4) being of separable design, and its outer race large enough to accommodate the bearing retaining nut(8).

More to follow....

A few years ago, when I acquired the machine, I contacted Fredrik Yman at Abene AB and he forwarded me a parts list/drawing set for my machine. Abene are now out of business (bankrupt in 2020) and the new owner (Vemu AB)have been unresponsive to my enquiries. There's very little info available on these machines...

302.1xx spindle (believed to be my 1964 year model)

According to that documentation, it is equipped with spindle assembly with part number series 302.1xx and a bearing arrangement consisting of double row cylindrical roller bearing (I believe with tapered bore similar to SKF NN3010K) at the business end, and a single row angular contact ball bearing and thrust ball bearing at rear end (seems redundant....more to follow)

I'm currently trying to disassemble the spindle to fix the leaking oil seal and I'm looking for some enlightenment !!

Firstly, the rear bearings are actually SKF 6207 (a regular deep groove ball bearing, not an angular contact bearing as the drawing above suggests), and a SKF 51110 thrust ball bearing. A slightly later spindle model 302.2xx shows the bearing as a regular deep groove ball bearing, consistent with that which I have found. It's drawing section is shown below (and is much clearer in its detail to the original 302.1xx drawing above. (note there's a slightly different numbering of the components).

302.2xx spindle (later year model)

With respect to disassembly, (and I've seen cwilcox's thread previously) I'm very nervous..

Abene Spindle Disassembly - Experience Requested

Referring to the drawing 302.2xx, I've removed all of the tail end components (18-29) except the deep groove ball bearing (17), and moved the circlip(12) which retains the bevel gear(10) toward the rear end of the spindle. It would now seem a simple matter of sliding the bevel gear along the spindle to allow the spindle to be pressed out trough its housing, the front roller bearing(4) being of separable design, and its outer race large enough to accommodate the bearing retaining nut(8).

More to follow....

Last edited: