Alan

Cast Iron

- Joined

- Nov 28, 2002

- Location

- Perth, Australia

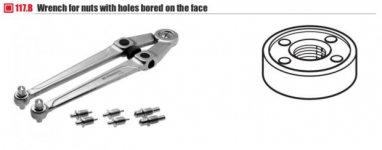

I'm in the process of giving the high speed head some much needed attention, trying to remove the bottom retaining ring on the spindle, unsure if left or right hand thread, but so far very reluctant to move, any advise appreciated.The collet size is 16mm.

Thanks Alan

Thanks Alan