karthikg89

Plastic

- Joined

- Jun 2, 2016

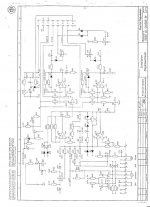

Hello! I have a Deckel FP2 activ toolroom mill. Recently due to a power fluctuation the drive went kaput with the MOVs(2 nos) getting fried. I have tried to repair it by replacing the MOVs but it won't work. Can anyone share the electrical drawings so that i can try to repair the drive? Also what are the specifications of the MOVs that need to be used? what other components of the drive need to be checked in such a case? The original ones were unidentifiable and i used what i thought would be the correct ones. Thanks is advance.