Hello everyone,

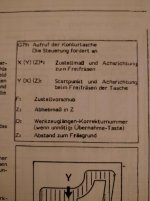

I am currently trying to understand the G79 contour pocketing cycle of my Deckel Fp2NC(2801) with Dialog 4

When programming a Pocket using the G79 contour pocketing command, I get the Error Code 88.

The control always mentions the error with the sentence which calls G79; e.g. Sentence N3 calls G79 I get the Error N3 88.

My documentation says error code 88 is a programming mistake, too small milling row pitch or the control is not capable of doing the G79 cycle.

I tried some of the sample G79 Programms from the Deckel Dialog 4 programming handbook with different cutter diameters, but even then error 88 strikes.

Is there a possibility to display the available G- and M- Codes on the operator control´s display?

How can be missing cycles be unlocked? Are the unlocked cycles independent from the Dialog 4 software version?

My Deckel has this software versions installed:

Can someone of you help me with my issues and provide me with some help?

Kind regards,

Markus

I am currently trying to understand the G79 contour pocketing cycle of my Deckel Fp2NC(2801) with Dialog 4

When programming a Pocket using the G79 contour pocketing command, I get the Error Code 88.

The control always mentions the error with the sentence which calls G79; e.g. Sentence N3 calls G79 I get the Error N3 88.

My documentation says error code 88 is a programming mistake, too small milling row pitch or the control is not capable of doing the G79 cycle.

I tried some of the sample G79 Programms from the Deckel Dialog 4 programming handbook with different cutter diameters, but even then error 88 strikes.

Is there a possibility to display the available G- and M- Codes on the operator control´s display?

How can be missing cycles be unlocked? Are the unlocked cycles independent from the Dialog 4 software version?

My Deckel has this software versions installed:

Can someone of you help me with my issues and provide me with some help?

Kind regards,

Markus