Sorry, no parts book here at home (lock down).

But i can tell you how the gearbox works....

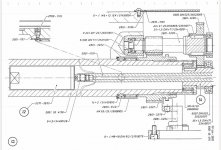

There are three snifter shafts that move the gears within the box.

Those shift shafts have a drum on each with a series of logs on the surface of each drum.

Each shaft also has micro switches in a carrier that allows the switches to ride on the drum surface and be activated by the lugs on the drum surface.

Believe there are 3 switches on each shaft/drum

Finally there are three small pancake motors at the outboard end of the shafts.

When a gear is selected, the machine simultaneously jogs the spindle using reduced voltage on the drive motor,and releasing the spindle brake....

At the same time power is applied to the shifting motors and they rotate until the proper set of contacts have been made.

Its a logic thing...when the proper set of contacts has been made, the shift motors are stopped and the spindle is started at full speed....

Note: the drive motor is two speed and the correct set of relay contacts are engaged to give the proper output spindle speed....

The jog sequence does 4 jog pulses in one direction then reverses for another 4 pulses, then 4 more in the original direction...all to help the gears mesh.

If the jog sequence does not result in getting all the needed switch contacts made for the selected speed, the machine faults to an emergency stop.

All this shifting is controlled by logic on cards within the large electrical cabinet (PC)

This is a complex system, and it would be difficult to replicate if you are missing much.

Further, if you are planning to shift teh gearbox by hand, be aware that there are no detents on the shift shafts....their position and proper gear mesh is defined by the cam and switch setup.

So to run manually, one would need to make some method of holding the gears in proper mesh for each gear set.

For my money the easiest work around for the gearbox, would be to devise a setup having two speed ranges that you could engage manually (one shift shaft hopefully)

and lock the other shift shafts in place .

Then fit the drive motor with an encoder, and run it using a commercial spindle drive (variable frequency)

The selection of the set gears would be such that you would get good torque over the widest range of speeds ...would need to do some math to find the best combination.

Cheers Ross