ballen

Diamond

- Joined

- Sep 25, 2011

- Location

- Garbsen, Germany

I got my Deckel FP2 about seven years ago. It's second generation, built in 1964.

When I got it there were some serious problems that needed attention. There were also some "little things" that I noticed but they didn't keep me from using the machine and didn't appear to be doing any damage, so I left them for "later".

One of those was a rumbling noise when the motor was running. I figured it was probably the motor bearings or the bearing on the upper motor pulley input shaft, which Peter and others here have said is usually damaged.

One of the other forum members here (Karl, Charly_DE) has been working on this part of his own FP2, and on the feed/speed boxes, and offered to help me with mine. He came over this past weekend with some bearings and seals that he had purchased alongside those for his own machine, and some extra gaskets that he had cut. Since he's just done this to his own machine, and knew exactly what was needed, it was very fast. We cleaned out the speed gearbox (which was not particularly dirty and and looked good inside):

which now also has a proper gasket instead of glue under the cover:

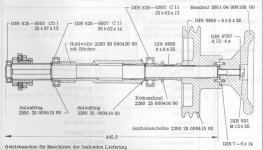

The more interesting part was around the rear power input shaft bearing, which in this photo is hidden behind the chain gear and lower circular flange/cover:

Removal of the rear bearing is straightforward if the vertical shaft which feeds power to the Y-axis feed can be disconnected. For example see the following post Deckel FP2 OIL LEAK and posts 5, 10 and 17 in that same thread. Post 13 in that thread has good photos of this feed.

I have never before removed the rear cover from my machine, but through the gaps I remember seeing an odd-looking "overlong" taper pin on the cylindrical piece that connects the lower feed shaft to the Y-axis drive at the top (the little stub sticking down at the top right of this photo):

The shaft (not shown, coming up from the bottom) is connected to this by a hollow cylinder attached top and bottom with taper pins. See the photos here: Deckel FP2 OIL LEAK . The idea is that to remove the input power feed shaft bearing, you drive out those taper pins and slide the hollow cylinder down. This provides enough clearance to lift and remove the lower shaft. Then you can access the bearing. (Alternatively you can grind off part of the flange, as described by Peter in the post linked above.)

Here you can see what was needed to remove that cylinder on my machine. The "odd looking taper pin" turned out to be a piece of a 4.2mm drill bit, crudely ground and hammered into place. But when Karl looked at the cylinder, he noticed a bulge near the taper pin hole, visible here:

In this photo you can see the source of that bulge, which is the remains of a taper pin, friction welded to the inside of the tube by a crash:

I think this is similar to what Dennis found inside the gearbox to his machine, where a taper pin had been sheared. Fortunately the access that we have here is better. For anyone who needs to remove this, a good method is to slit it lengthwise with a fine abrasive cutting wheel on a Dremel, going almost to the top. Then spread it with a nut splitter:

When I am done making it, I'll post a photo of the replacement for this part, which will be the same on the bottom as the normal cylinder but on the top will be secured with a split clamp and pin.

By the way, as Peter had predicted, the rear input bearing was worn/noisy. It's now been replaced with a new ********* 2RS bearing from which the inner seal (and grease) have been removed. Outer seal is intact.

The other source of noise is the motor pulley, which has a 24mm keyed shaft. The grub screw holding down the key was loose, and the pulley has wobbled enough to wear the shaft and key slot. I've got the motor apart now to replace the bearings. I will probably grind the shaft between centers down to 23.8mm and bush the pulley for an interference fit on that shaft.

An interesting question is, how did the power mechanism create enough torque to do the damage shown above? We checked and the shear pin mechanism is working as it should. A 2mm soft steel pin can not transmit enough power to do such violence. My theory is that the Y axis was crashed during a rapid move where the Z axis was moving downwards. The energy source for the damage was NOT the normal feed mechanism, but rather the kinetic energy of the mill table and support moving downwards. These can transmit that energy to the feed shaft that runs from front to back through the bottom of the machine, and via that path to the Y-axis feed shaft.

Moral of the story: make sure Y is stopped when doing X or Z moves!

Karl, thanks again for your help!

After I am done with the motor and the new shaft coupling, now that the machine is apart, I guess it's finally time to paint the side and back covers...

Cheers,

Bruce

When I got it there were some serious problems that needed attention. There were also some "little things" that I noticed but they didn't keep me from using the machine and didn't appear to be doing any damage, so I left them for "later".

One of those was a rumbling noise when the motor was running. I figured it was probably the motor bearings or the bearing on the upper motor pulley input shaft, which Peter and others here have said is usually damaged.

One of the other forum members here (Karl, Charly_DE) has been working on this part of his own FP2, and on the feed/speed boxes, and offered to help me with mine. He came over this past weekend with some bearings and seals that he had purchased alongside those for his own machine, and some extra gaskets that he had cut. Since he's just done this to his own machine, and knew exactly what was needed, it was very fast. We cleaned out the speed gearbox (which was not particularly dirty and and looked good inside):

which now also has a proper gasket instead of glue under the cover:

The more interesting part was around the rear power input shaft bearing, which in this photo is hidden behind the chain gear and lower circular flange/cover:

Removal of the rear bearing is straightforward if the vertical shaft which feeds power to the Y-axis feed can be disconnected. For example see the following post Deckel FP2 OIL LEAK and posts 5, 10 and 17 in that same thread. Post 13 in that thread has good photos of this feed.

I have never before removed the rear cover from my machine, but through the gaps I remember seeing an odd-looking "overlong" taper pin on the cylindrical piece that connects the lower feed shaft to the Y-axis drive at the top (the little stub sticking down at the top right of this photo):

The shaft (not shown, coming up from the bottom) is connected to this by a hollow cylinder attached top and bottom with taper pins. See the photos here: Deckel FP2 OIL LEAK . The idea is that to remove the input power feed shaft bearing, you drive out those taper pins and slide the hollow cylinder down. This provides enough clearance to lift and remove the lower shaft. Then you can access the bearing. (Alternatively you can grind off part of the flange, as described by Peter in the post linked above.)

Here you can see what was needed to remove that cylinder on my machine. The "odd looking taper pin" turned out to be a piece of a 4.2mm drill bit, crudely ground and hammered into place. But when Karl looked at the cylinder, he noticed a bulge near the taper pin hole, visible here:

In this photo you can see the source of that bulge, which is the remains of a taper pin, friction welded to the inside of the tube by a crash:

I think this is similar to what Dennis found inside the gearbox to his machine, where a taper pin had been sheared. Fortunately the access that we have here is better. For anyone who needs to remove this, a good method is to slit it lengthwise with a fine abrasive cutting wheel on a Dremel, going almost to the top. Then spread it with a nut splitter:

When I am done making it, I'll post a photo of the replacement for this part, which will be the same on the bottom as the normal cylinder but on the top will be secured with a split clamp and pin.

By the way, as Peter had predicted, the rear input bearing was worn/noisy. It's now been replaced with a new ********* 2RS bearing from which the inner seal (and grease) have been removed. Outer seal is intact.

The other source of noise is the motor pulley, which has a 24mm keyed shaft. The grub screw holding down the key was loose, and the pulley has wobbled enough to wear the shaft and key slot. I've got the motor apart now to replace the bearings. I will probably grind the shaft between centers down to 23.8mm and bush the pulley for an interference fit on that shaft.

An interesting question is, how did the power mechanism create enough torque to do the damage shown above? We checked and the shear pin mechanism is working as it should. A 2mm soft steel pin can not transmit enough power to do such violence. My theory is that the Y axis was crashed during a rapid move where the Z axis was moving downwards. The energy source for the damage was NOT the normal feed mechanism, but rather the kinetic energy of the mill table and support moving downwards. These can transmit that energy to the feed shaft that runs from front to back through the bottom of the machine, and via that path to the Y-axis feed shaft.

Moral of the story: make sure Y is stopped when doing X or Z moves!

Karl, thanks again for your help!

After I am done with the motor and the new shaft coupling, now that the machine is apart, I guess it's finally time to paint the side and back covers...

Cheers,

Bruce