StefanG

Aluminum

- Joined

- Dec 3, 2009

- Location

- Germany, Bavaria

Hi,

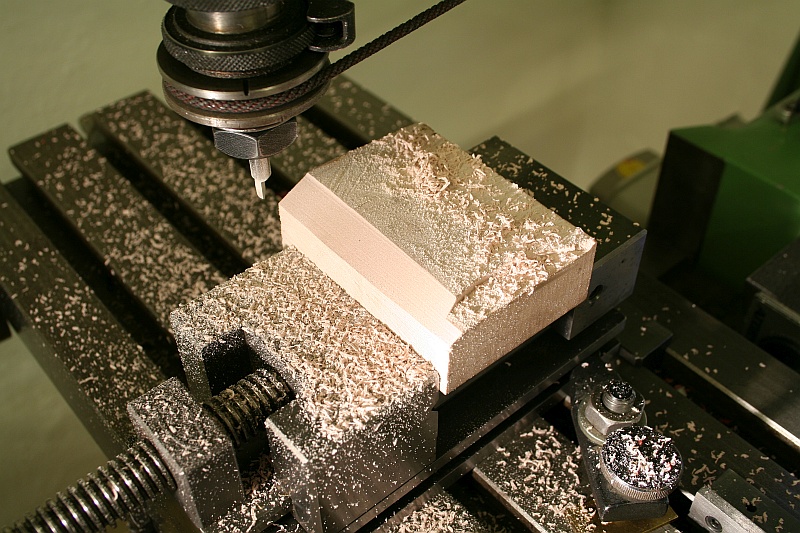

Yesterday I took a look at a Deckel G1L pantograph and as it was in real great condition I just took it home

It showed that the machine was used in Munich at a BMW plant and found very little use. Because of that it got sold to one of the workers, where it collected dust for about eight years, now he wanted to get rid of it.

The paint is in very good condition, as well as the ways, which look as they have moved no more than a few times. On the end of the ways and on many other parts there was still the brown preservation wax and nothing was dinged up or hacked with a channellock..

An thats what i got:

Looks nice next to the Deckel G2NC:

And thats what came with the machine:

- Manual and part list

- Machine card

- Deckel engraving cutters with the conical shank (and the collet adapter for conical shanks)

- Patternholder

- Clamps

- Some tools

Also there are three boxes of letters in different styles and spare belts:

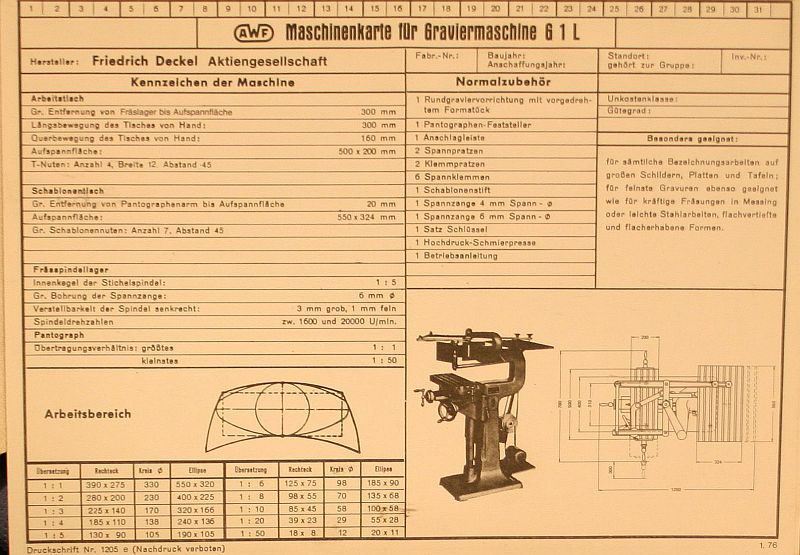

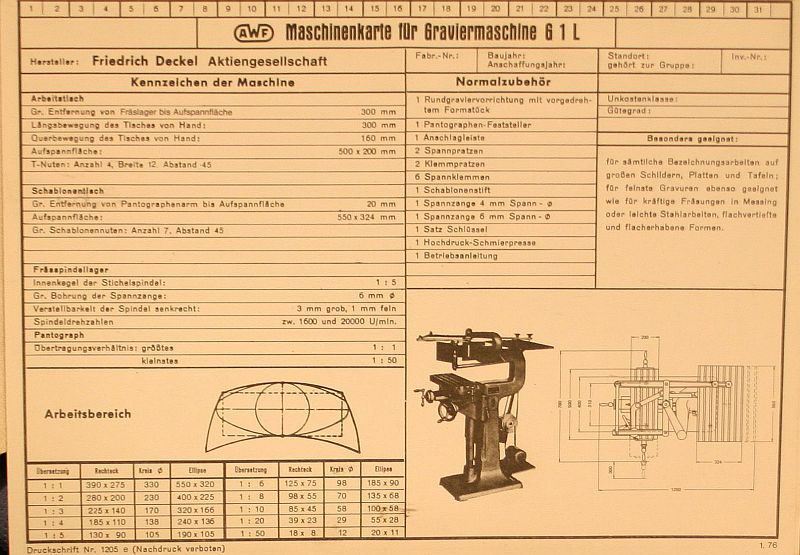

I love those machine cards that list all of the machines key specifications:

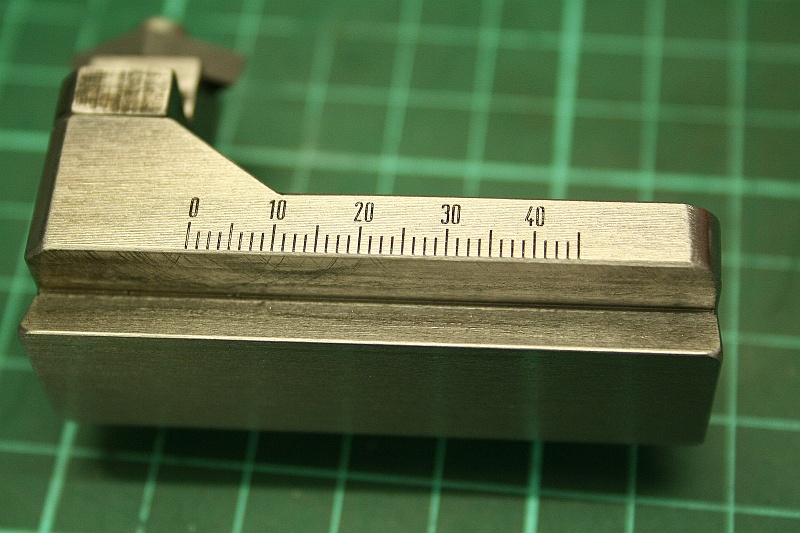

Only thing thats missing are collets with a straight bore, and Mr. Singer takes a fortune those, so I will make those by myself.

And what will it be used, as I allready have a cnc milling machine? It will be used for my personal enjoyment. And maybe make a fortune engraving signs for friends

But I also want to use its wide range of reducing which ranges from 1:1 down to 1:50 to machine very small parts for model engineering.

Stefan

Yesterday I took a look at a Deckel G1L pantograph and as it was in real great condition I just took it home

It showed that the machine was used in Munich at a BMW plant and found very little use. Because of that it got sold to one of the workers, where it collected dust for about eight years, now he wanted to get rid of it.

The paint is in very good condition, as well as the ways, which look as they have moved no more than a few times. On the end of the ways and on many other parts there was still the brown preservation wax and nothing was dinged up or hacked with a channellock..

An thats what i got:

Looks nice next to the Deckel G2NC:

And thats what came with the machine:

- Manual and part list

- Machine card

- Deckel engraving cutters with the conical shank (and the collet adapter for conical shanks)

- Patternholder

- Clamps

- Some tools

Also there are three boxes of letters in different styles and spare belts:

I love those machine cards that list all of the machines key specifications:

Only thing thats missing are collets with a straight bore, and Mr. Singer takes a fortune those, so I will make those by myself.

And what will it be used, as I allready have a cnc milling machine? It will be used for my personal enjoyment. And maybe make a fortune engraving signs for friends

But I also want to use its wide range of reducing which ranges from 1:1 down to 1:50 to machine very small parts for model engineering.

Stefan