Fastguido

Aluminum

- Joined

- Nov 20, 2003

- Location

- Reno,Nevada USA

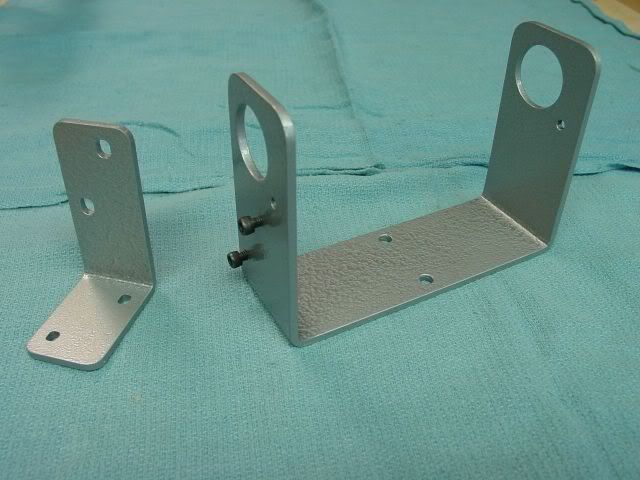

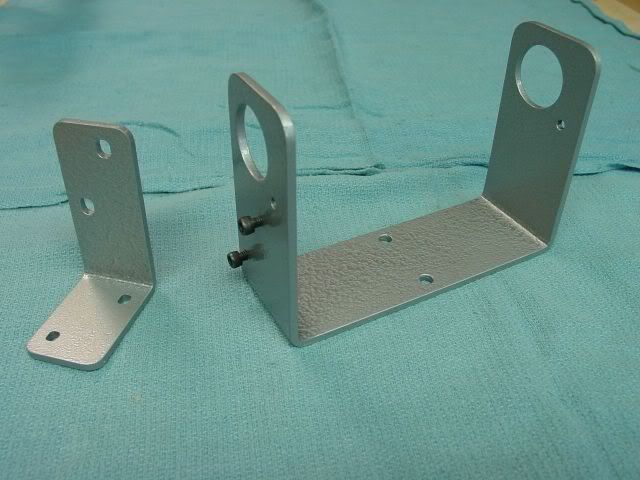

Needed a coolant system for the mill, I have the stock flood system, but I don't have a chip tray, so the flood coolant is out. During my search on alternatives systems, I found the patent papers on the "Fogbuster". I decided to build one for the Deckel. I ordered a water filter container and a needle valve from McMaster-Carr. Found a new surplus 24 volt solenoid valve and 220 volt to 24 volt control tranformer on EBAY. I first made a bracket to hold the filter container and solenoid,

Mounted the container/solenoid/air regulator on the bracket,

Purchased a small plasic box and mounted the tranformer, a terminal block, and a fuse holder in the box,

I then mounted the box on the back panel of the Deckel's colunm. I used the stock Deckel conduit/wiring that used to go to the flood system pump to go to the input of the transformer,

I have to give a big shout out to Ross, for making me that back panel, it was missing when I got the mill. I just asked him for the dimensions of the panel, but what shows up at the front door- a completed back panel! Thanks again Ross.

I then made the nozzle assy as per the patent and used the stock Deckel flood piping with some line-lock for the air supply.

Here is the completed container/solenoid assy. mounted on the wall behind the mill. It works great, except I am going to put a one way check valve on the coolant supply hose. The coolant drains back to the container when the coolant is switched off.

Monte

Mounted the container/solenoid/air regulator on the bracket,

Purchased a small plasic box and mounted the tranformer, a terminal block, and a fuse holder in the box,

I then mounted the box on the back panel of the Deckel's colunm. I used the stock Deckel conduit/wiring that used to go to the flood system pump to go to the input of the transformer,

I have to give a big shout out to Ross, for making me that back panel, it was missing when I got the mill. I just asked him for the dimensions of the panel, but what shows up at the front door- a completed back panel! Thanks again Ross.

I then made the nozzle assy as per the patent and used the stock Deckel flood piping with some line-lock for the air supply.

Here is the completed container/solenoid assy. mounted on the wall behind the mill. It works great, except I am going to put a one way check valve on the coolant supply hose. The coolant drains back to the container when the coolant is switched off.

Monte