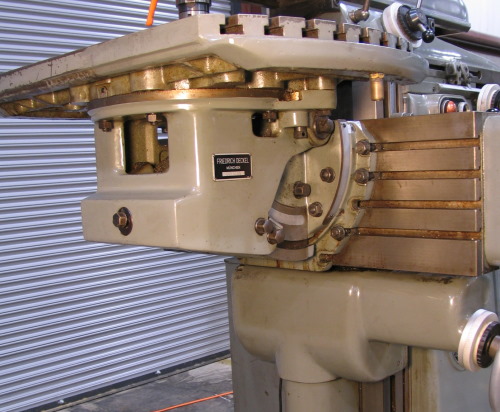

AB has another one priced high enough (for what it is...1st gen, straight table, no major tooling with it, etc) that we'll be seeing the ad for the rest of our lives....at least it's reasonably pleasant to look at, unlike the decrepite looking FP2's that keep popping up..

http://cgi.ebay.com/DECKEL-FP2-UNIV...ryZ12584QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

http://cgi.ebay.com/DECKEL-FP2-UNIV...ryZ12584QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

)

)