Hello Panza,

Glad to have helped you figure out the problem. Usually turns out that the machine control is right more then it's wrong.

I have a lot of mill programming experience but am still a complete newb on lathes. Yet I can visualize how to do this part easily with X and C and of course Z if you need it. EDIT: I re-read your post and see you're having thoughts along the same idea I list below.

First what I might do is drill out all the corners with a slightly under-size drill. That or an oversize one shifted slightly as to not touch the finished profile. If this is production I would only drill out a single starting corner in each separate work areas.

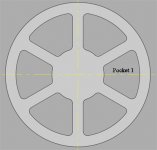

I would position the tool over the feature area's corner hole you just drilled, and from that point on I would program all the milling with 100% incremental (U-W-H) movements and put those movements in a subroutine. Then all you do is position the tool in X,C and Z, and call up the subroutine. In fact if you ended your tool where you started, or even if you didn't, at the very end of your subroutine you could also include a retract to clearance plain and a new H60 (incremental 60 deg C move) and whatever other moves you'd need to get to the next start position, and simply call your subroutine with a 6 times repeat count. M98P1000L6 and as example using subroutine O1000. At the end of six repeats your tool would move one extra time to the initial start position, but it wouldn't actually do anything else from there except move the turret to clear for the next tool change. Meaning there would be a tiny amount of wasted movement after the last mill op, but so what.

That's how I would do it. But it would take me forever as my lathe speed programming skills are minimal. This could also be done super easy on a mill too.