VictorStefan

Plastic

- Joined

- Oct 18, 2017

Hello all,

I have a problem when im trying to cut with angle.

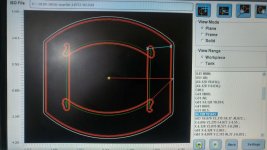

As you can see in the photos (white countour is the main profile), i have problems when i try to cut with taper inside the original profile.

When i try to cut with taper outside the profile i have no problem...

Any1 is familiar with CUT20P erosion machine?

I have a problem when im trying to cut with angle.

As you can see in the photos (white countour is the main profile), i have problems when i try to cut with taper inside the original profile.

When i try to cut with taper outside the profile i have no problem...

Any1 is familiar with CUT20P erosion machine?