A hossfeld will do it.

Hossfeld Bender Catalogs | Hossfeld Dies and Parts | QuickStart™ Toolsets | Hossfeld Universal Bender

page 37 on the universal catalog 100 here.

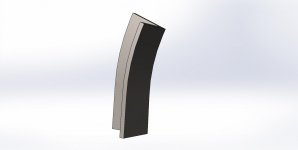

this is a standard die for a hossfeld- its a 42980 angle iron heel outward die. they are sold in two sided dies, each one has 2 fixed radiuses.

You would need to buy a basic hossfeld, around $650, and then these dies- probably get the whole shebang, new, from Hossfeld, for around a grand.

Call em and ask.

Yep, its an armstrong tool (you use your own muscle to bend it) but the mechanical leverage advantage is enough that its no big deal. You could knock these out in a couple of hours.

This would be the cheapest, fastest way to do it- no machining, no custom dies, no wondering if it will work after you spend two days making tooling.

Hossfelds work.

They figgered it out fifty or sixty years ago.

Lots of people who have never done this will offer suggestions they think might work, if you build custom tooling.

They have never used a hossfeld.

(Francis Whittaker was a cute ol' curmudgeon, but he wasnt any kind of fabricator, and he pretty much never made more than one of anything in his life. He had no clue about any 20th century metalworking techniques. He was a great introduction for teenagers into blacksmithing, but his technique will take you an hour each piece. He got paid to teach, not make parts)