Just finished building a Certiflat 24"x48" FabBlock welding/fixture table from weld tables .com. Pretty happy with the fit/quality. It's made with 3/8" thick plate, with alternating 16mm holes and tapped 1/2-13 on 2" centers.

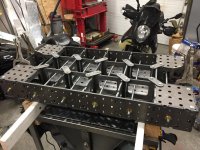

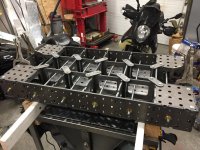

A shot of the raw components.

Clamped the daylights out of it, and tacked it together. Fit of the components was snug, but never took more than a light rap with a dead blow to assemble.

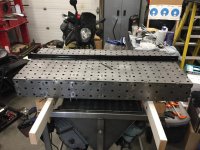

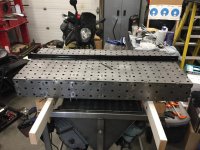

Flipped right side up, checked for flatness, and tacked the top, and checked flatness once more. The straight edge is supposed to be straight to within .003". I put it across the top at 12" intervals, crossways, longways, and diagonally( straight edge is only 50", so couldn't quite reach corner to corner). When there was a visible gap(shining a bright light from behind)the thickest feeler gauge I could slip under was .010". They claimed that .015" or better was possible, so I'm pleased with the results.

The mobile base is made with 1-1/2x2-1/2x3/16 wall tube. It was from a battery stand from work that was scrapped. Also included leveling pads, for when needed. Intent is to only use this for TIG to keep it clean. Had a 14ga topper bent up to cover it, for MIG and stick.

A shot of the raw components.

Clamped the daylights out of it, and tacked it together. Fit of the components was snug, but never took more than a light rap with a dead blow to assemble.

Flipped right side up, checked for flatness, and tacked the top, and checked flatness once more. The straight edge is supposed to be straight to within .003". I put it across the top at 12" intervals, crossways, longways, and diagonally( straight edge is only 50", so couldn't quite reach corner to corner). When there was a visible gap(shining a bright light from behind)the thickest feeler gauge I could slip under was .010". They claimed that .015" or better was possible, so I'm pleased with the results.

The mobile base is made with 1-1/2x2-1/2x3/16 wall tube. It was from a battery stand from work that was scrapped. Also included leveling pads, for when needed. Intent is to only use this for TIG to keep it clean. Had a 14ga topper bent up to cover it, for MIG and stick.