Hi,

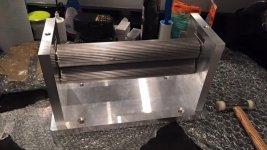

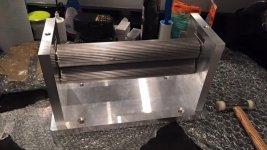

I'm new here and am looking for some guidance on the design of a sheet metal roller.

I am designing and manufacturing a 2 roll hand operated roller which has a 320mm roller length.

The bottom roller is fixed whilst the top roller requires adjustable up and down movement.

Below are 2 photos of the one I have manufactured.

I found a design on this forum (photo below) and would like to know how the brass bush slides move up and down and retain the threaded tommy bar bolt for up and down movement? I don't see any grub screw which would retain the bolt?

Any different design configurations and ideas would be much appreciated also.

I'm new here and am looking for some guidance on the design of a sheet metal roller.

I am designing and manufacturing a 2 roll hand operated roller which has a 320mm roller length.

The bottom roller is fixed whilst the top roller requires adjustable up and down movement.

Below are 2 photos of the one I have manufactured.

I found a design on this forum (photo below) and would like to know how the brass bush slides move up and down and retain the threaded tommy bar bolt for up and down movement? I don't see any grub screw which would retain the bolt?

Any different design configurations and ideas would be much appreciated also.