adamsgt

Cast Iron

- Joined

- Nov 7, 2007

- Location

- Fort Worth Texas

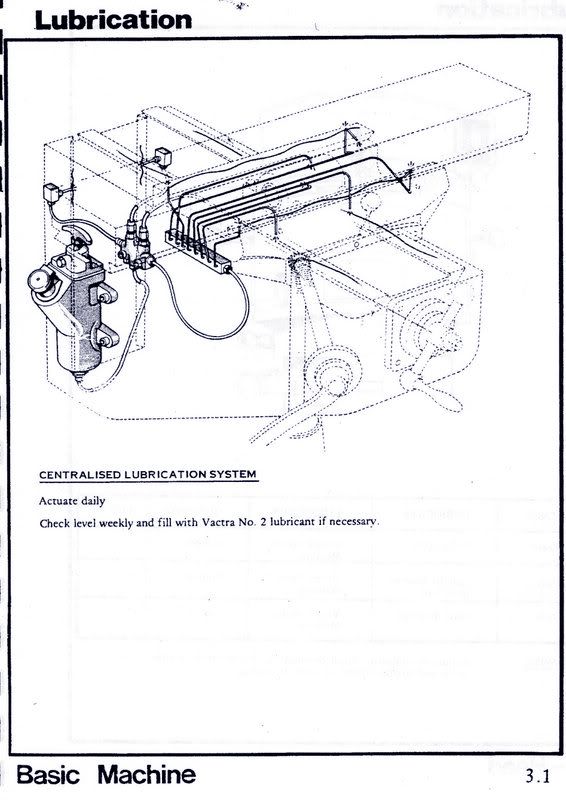

I have a few question about the one shot lubrication system installed on the used mill I bought.

First there are a couple of sections of tubing hanging loose. One comes down inside the knee from the top. The other comes from the right side of the pump.

I looked under the knee at the screw post and saw a fitting which may be where the tubing coming out of the pump goes.

I connected the tubing to the fitting under the knee.

Still don't know what that other piece of tubing is for. My first thought is that this might be the end of the lubrication runs to allow the lube to flow. I have no second thought. Help please?

Few more questions.

What type of lube should I be putting into this system. How often should it be used and how do you tell when you've lubed enough?

What is the grate covering? I can tell it's not leaking on the floor. Well, I really can't get down that far as my knees are still too stiff from two knee replacements.

I noticed an oil port on the head of the mill. Again, what kind of oil and how much and how often?

Whew, that's a bunch of stuff.

And I have no idea of why I have a piece of paper with OBGYN on it. Well, maybe that's because I had to look up the mills knee.

First there are a couple of sections of tubing hanging loose. One comes down inside the knee from the top. The other comes from the right side of the pump.

I looked under the knee at the screw post and saw a fitting which may be where the tubing coming out of the pump goes.

I connected the tubing to the fitting under the knee.

Still don't know what that other piece of tubing is for. My first thought is that this might be the end of the lubrication runs to allow the lube to flow. I have no second thought. Help please?

Few more questions.

What type of lube should I be putting into this system. How often should it be used and how do you tell when you've lubed enough?

What is the grate covering? I can tell it's not leaking on the floor. Well, I really can't get down that far as my knees are still too stiff from two knee replacements.

I noticed an oil port on the head of the mill. Again, what kind of oil and how much and how often?

Whew, that's a bunch of stuff.

And I have no idea of why I have a piece of paper with OBGYN on it. Well, maybe that's because I had to look up the mills knee.