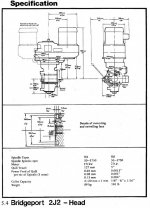

Hello everyone, always wanted to join this board and now I have a legitimate reason. I just purchased a 1973 Bridgeport with an M head. I am a metal fabricator and welder and I have been hoping to learn how to use a mill and lathe to expand my metalworking capabilities. The chance came to purchase a bridgeport so I jumped on it immediately. I had no chance to do my research beforehand, unfortunately, so as I am reading about my machine now I am learning this might not have been the best purchase! I have very little knowledge about these machines and I have used a knee mill only a handful of times (a Cheng Ki 1-1/2hp). What do you guys think about this machine? Is it possible to buy a J head and mount it on this machine if I want something heavier duty with auto-feed?

$2,000 for the machine in good condition.

Serial on the Knee "12 BR 157759"

Serial on the Head "M26493"

Motor 1/2 HP

Thank you for your time.

(not sure if this is the best way to attach pics)

$2,000 for the machine in good condition.

Serial on the Knee "12 BR 157759"

Serial on the Head "M26493"

Motor 1/2 HP

Thank you for your time.

(not sure if this is the best way to attach pics)