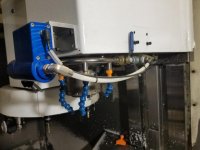

Right off the bat - I dont make this system but may receive a slave servo head for helping to make it work with a Fadal. Either way I purchased a servo unit at full price since I thought I could make it work. Right now the system runs about ~$700 since its in prototype phase.

For the last 3 years I've been looking for a servo coolant system for my Fadal. Flood nozzles are ok but a pain for long drill bits to endmill tool changes. I looked into piecing together a original Fadal servo coolant system with amplifier, controller card and associated hardware. Not a easy task nor cheap. Almost purchased a really old Spidercool kit off Ebay and even debated spending 4k on a Spidercool system. For normal shops the cost is easier to justified but for a part time home shop the cost was too high. I found Accublast was a new company producing a new servo blast system but the unit wasnt tested on a Fadal mill.

Peter from Accublast and I exchanged a few emails with details on how the system functioned while I researched the I/O on the fadal. Once the system arrived I tried a few different methods of interfacing the Accublast I/O board into the fadal I/O. The final method was using a IDC34 breakout board to tie into a ribbon cable from the 1060 computer chassis board. Add a few 5v relays to the mix then off to the Accublast I/O card. We had to modify the programming on the Accublast system to account for the relay bounce and how the Fadal signals are different then other systems.

System can use either the Haas ethernet, serial dprint or I/O to set which tool is being used. On the Fadal the system is looking at the CW and CCW tool changer I/O points and the hall effect sensor to keep track of the tool pocket. System is easy to setup once installed. Power up mill, set current tool pocket on the display board, set angle of coolant nozzle and if you want a twitch motion on the nozzles. The Fadal servo unit requires gcode programming to function versus the easier Accublast display unit. Gcode would be better for production runs to avoid button pusher from moving shit.

I'm trying to convince the manufacture to make a plug and play board to make install a lot easier for everyone. A few friends would love this system but need a simpler install that what I have. I still need to do long term testing on the setup but over 70 tool changes have been flawless.

I also have a PDF of the wiring schematic used for the system which includes the part numbers used. If the pictures dont work well enough for you. Send a pm for a copy.

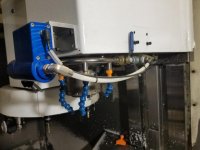

For the last 3 years I've been looking for a servo coolant system for my Fadal. Flood nozzles are ok but a pain for long drill bits to endmill tool changes. I looked into piecing together a original Fadal servo coolant system with amplifier, controller card and associated hardware. Not a easy task nor cheap. Almost purchased a really old Spidercool kit off Ebay and even debated spending 4k on a Spidercool system. For normal shops the cost is easier to justified but for a part time home shop the cost was too high. I found Accublast was a new company producing a new servo blast system but the unit wasnt tested on a Fadal mill.

Peter from Accublast and I exchanged a few emails with details on how the system functioned while I researched the I/O on the fadal. Once the system arrived I tried a few different methods of interfacing the Accublast I/O board into the fadal I/O. The final method was using a IDC34 breakout board to tie into a ribbon cable from the 1060 computer chassis board. Add a few 5v relays to the mix then off to the Accublast I/O card. We had to modify the programming on the Accublast system to account for the relay bounce and how the Fadal signals are different then other systems.

System can use either the Haas ethernet, serial dprint or I/O to set which tool is being used. On the Fadal the system is looking at the CW and CCW tool changer I/O points and the hall effect sensor to keep track of the tool pocket. System is easy to setup once installed. Power up mill, set current tool pocket on the display board, set angle of coolant nozzle and if you want a twitch motion on the nozzles. The Fadal servo unit requires gcode programming to function versus the easier Accublast display unit. Gcode would be better for production runs to avoid button pusher from moving shit.

I'm trying to convince the manufacture to make a plug and play board to make install a lot easier for everyone. A few friends would love this system but need a simpler install that what I have. I still need to do long term testing on the setup but over 70 tool changes have been flawless.

I also have a PDF of the wiring schematic used for the system which includes the part numbers used. If the pictures dont work well enough for you. Send a pm for a copy.