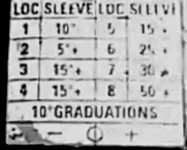

By the way, you are aware that that chart is only for parabolic drills, right? It's only meant as a rough guide. Normal drills should be very close to splitting right at the chisel at 0° and the manual says for crankshaft split, turn the collar to 15° clockwise (+ direction) and for a reduced rake like for drilling brass, to 40° clockwise. Personally I like a little more toward 20° - 25° for what's more of a modified split point. These tend to start better without wandering or tri-lobing in my opinion. At any rate, the given numbers are just a guideline - you may need to tweak a little depending on included angle and drill geometry.