pritchaj

Plastic

- Joined

- Jun 4, 2014

- Location

- Bay Area, CA, United States

Hey All,

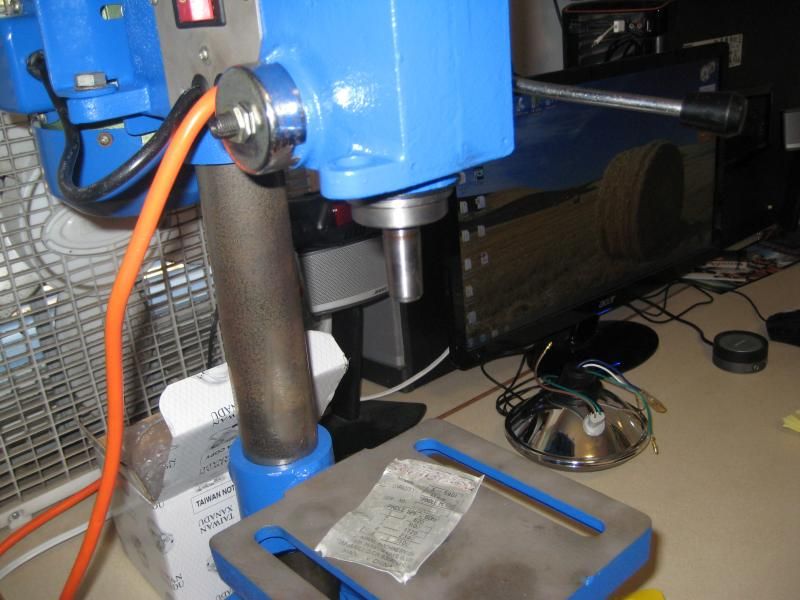

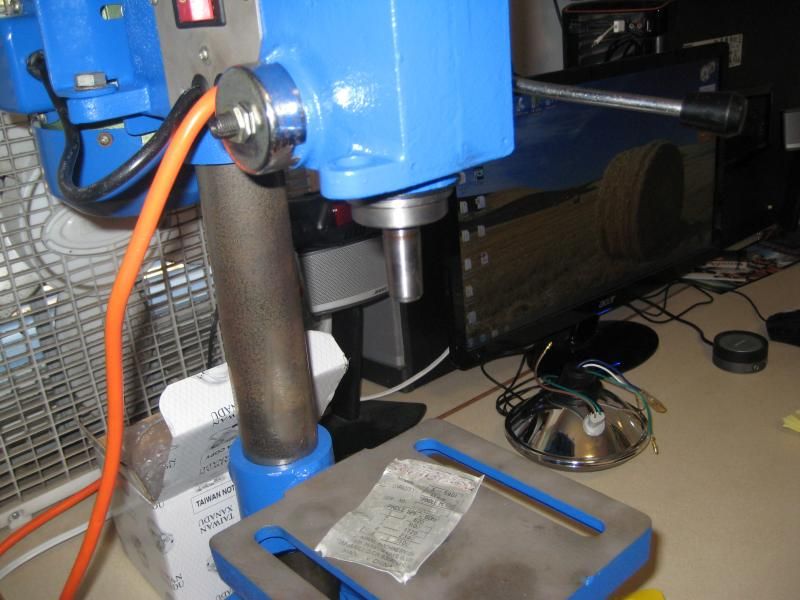

I recently was given an old bench top drill press from my brother. It was one of two that he got from some old guys garage sale for $10. So, I thought I would scrub off the rust and repaint it and then just buy a cheap chuck (the one it come with is broken).

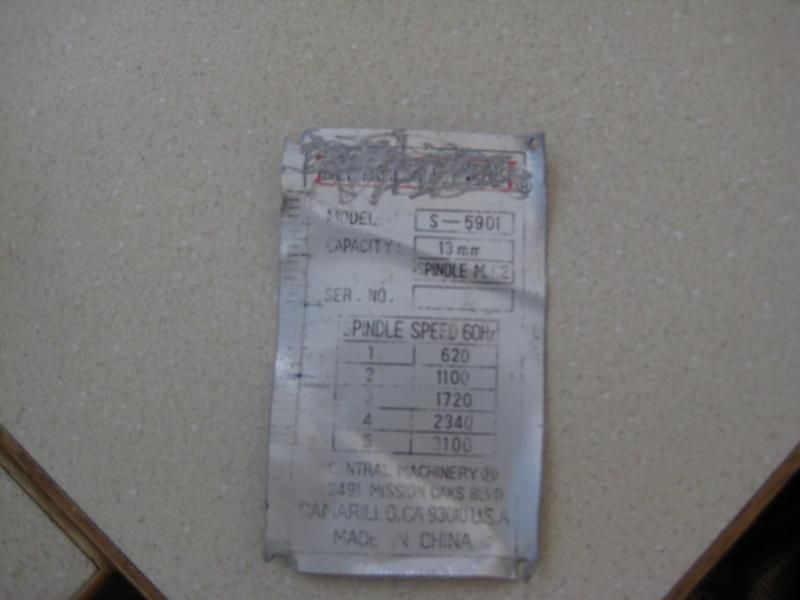

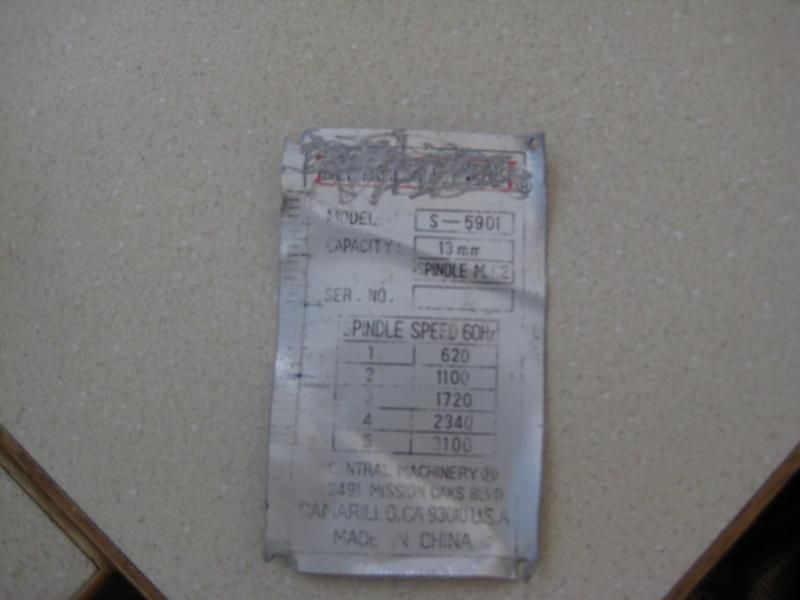

It is a Central Machinery model: S-5901, made in China. The measurements for the spindle are:

Larger diameter: 0.628"

Smaller diameter: 0.579"

Length: 1.025"

Looking at the different taper dimensions this is closest to a Jacobs Taper #33. I bought a cheap JT33 chuck off amazon and thing won't seat fully on the spindle. It's like the taper angles don't match and it allows the chuck to wobble. Then when removing the chuck I can seen two shiny spots where it was mating with the spindle. Then I got my hands and a good name brand JT33 chuck and it was the same story. The original (broken) chuck fits on snug as bug, so I am at a loss of how to get a functional chuck for this DP, any suggestions?

If you look at the pic of the data plate you'll see it says the spindle is a MT2, but that is a lie. When I took it apart to repaint it, the upper spindle is just a .400" straight shank pressed into some bearings. So, I'm wondering if this just a case of cheap chinese made junk, thanks for any help you guys can offer.

Jon

I recently was given an old bench top drill press from my brother. It was one of two that he got from some old guys garage sale for $10. So, I thought I would scrub off the rust and repaint it and then just buy a cheap chuck (the one it come with is broken).

It is a Central Machinery model: S-5901, made in China. The measurements for the spindle are:

Larger diameter: 0.628"

Smaller diameter: 0.579"

Length: 1.025"

Looking at the different taper dimensions this is closest to a Jacobs Taper #33. I bought a cheap JT33 chuck off amazon and thing won't seat fully on the spindle. It's like the taper angles don't match and it allows the chuck to wobble. Then when removing the chuck I can seen two shiny spots where it was mating with the spindle. Then I got my hands and a good name brand JT33 chuck and it was the same story. The original (broken) chuck fits on snug as bug, so I am at a loss of how to get a functional chuck for this DP, any suggestions?

If you look at the pic of the data plate you'll see it says the spindle is a MT2, but that is a lie. When I took it apart to repaint it, the upper spindle is just a .400" straight shank pressed into some bearings. So, I'm wondering if this just a case of cheap chinese made junk, thanks for any help you guys can offer.

Jon