Bill D

Diamond

- Joined

- Apr 1, 2004

- Location

- Modesto, CA USA

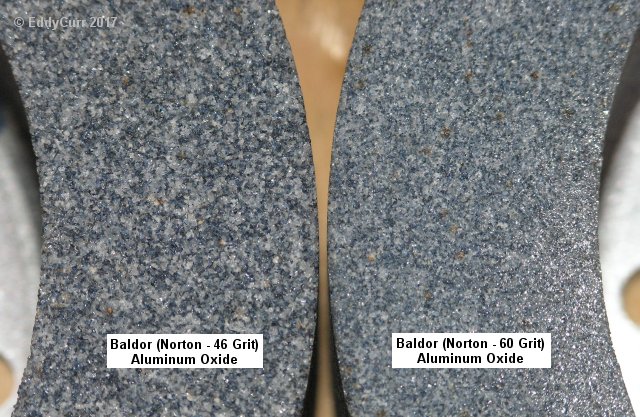

I am trying to search about replacement grinding wheels for a Baldor 6" tool and cutter grinder. these have a central hole to locate the wheel and four smaller bolts to hold it on.

I have seen them called plain, cup,dish, dished, bowl, mounted, plated, plate and a few other terms. problem is all these terms seem to also be used for other types of grinding stones. Most with just one central mounting hole.

is there a correct term to search for?

Also is there any way to force ebay to only look for 6" wheels? when I search for " 6" " it returns anything with a 6 anywhere in the description or model number.

Bill D

I have seen them called plain, cup,dish, dished, bowl, mounted, plated, plate and a few other terms. problem is all these terms seem to also be used for other types of grinding stones. Most with just one central mounting hole.

is there a correct term to search for?

Also is there any way to force ebay to only look for 6" wheels? when I search for " 6" " it returns anything with a 6 anywhere in the description or model number.

Bill D