Clive603

Titanium

- Joined

- Aug 2, 2008

- Location

- Sussex, England

So I have a practical back of the envelope level concept for a quick detachable dooby. I have an effective way to do the QD bit with a screw thread but its less than neat. More concept demonstrator than something I'd want to use.

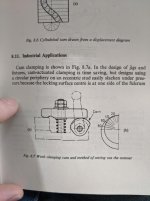

I'd much prefer some sort of part turn, steel on steel, jamming eccentric device as used camloc chuck fittings, QD toolposts and all sorts of other things.

But I don't have any details on how to design such a thing so it doesn't come loose on its own and is able to generate enough holding force to stop the device moving. Heck I don't even know what the proper name for such things is so I can start looking on t'net.

I imagine the actual locking action is similar to that of a taper drill in merely requiring that the angle between the fixed and moving components is sufficiently small, but not flat on flat, for things to hold. Presumably there is some relationship between angle and area to define holding force. Ideally I'd like to get the surface forces down to a level that doesn't require hardened components.

From old catalogue pictures I know that sufficiently similar devices have been made to work well in the past so its clearly possible. Its just finding a design resource that has me stumped. I'd rather not follow the "monkey see, monkey do" approach of simply copying and re-dimensioning the camloc, QD tool post and other small systems I have to hand.

Thanks for any help.

Clive

I'd much prefer some sort of part turn, steel on steel, jamming eccentric device as used camloc chuck fittings, QD toolposts and all sorts of other things.

But I don't have any details on how to design such a thing so it doesn't come loose on its own and is able to generate enough holding force to stop the device moving. Heck I don't even know what the proper name for such things is so I can start looking on t'net.

I imagine the actual locking action is similar to that of a taper drill in merely requiring that the angle between the fixed and moving components is sufficiently small, but not flat on flat, for things to hold. Presumably there is some relationship between angle and area to define holding force. Ideally I'd like to get the surface forces down to a level that doesn't require hardened components.

From old catalogue pictures I know that sufficiently similar devices have been made to work well in the past so its clearly possible. Its just finding a design resource that has me stumped. I'd rather not follow the "monkey see, monkey do" approach of simply copying and re-dimensioning the camloc, QD tool post and other small systems I have to hand.

Thanks for any help.

Clive