Shawn_Laughlin

Aluminum

- Joined

- Mar 28, 2019

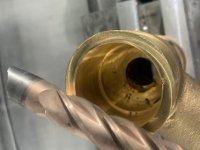

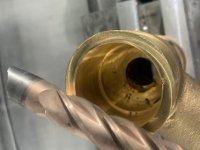

I have a hole I need to make in 3 parts that I was previously interpolating with a long 3/4 end mill but I shattered it last night and need to get these things done.

So I was thinking since the part already has a hole cast into it and since the hole I need to cut and my indexable end mill are the same diameter, I was wondering if y’all think this cutter could wing it until my proper drill bit comes in?

The material is a brass c84400 to be exact

So I was thinking since the part already has a hole cast into it and since the hole I need to cut and my indexable end mill are the same diameter, I was wondering if y’all think this cutter could wing it until my proper drill bit comes in?

The material is a brass c84400 to be exact