David_M

Hot Rolled

- Joined

- Sep 30, 2014

- Location

- Midway, GA, USA

After asking numerous questions myself, I think I have a couple of thoughts that might be worth sharing.

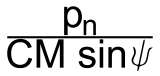

Formula for hobbing helical gears:

KCT

(CN) ± 1

K = machine index constant

C = C constant

T = number of threads on hob

N = number of teeth on gear

1 = absolute constant

M = feed constant

Sample:

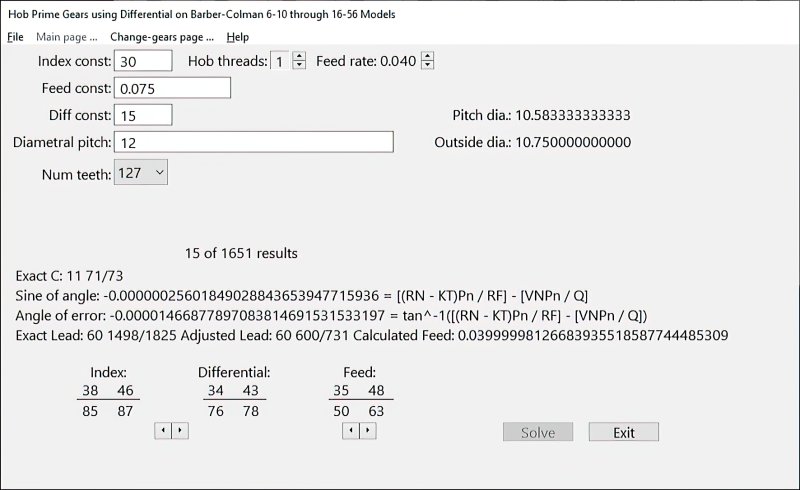

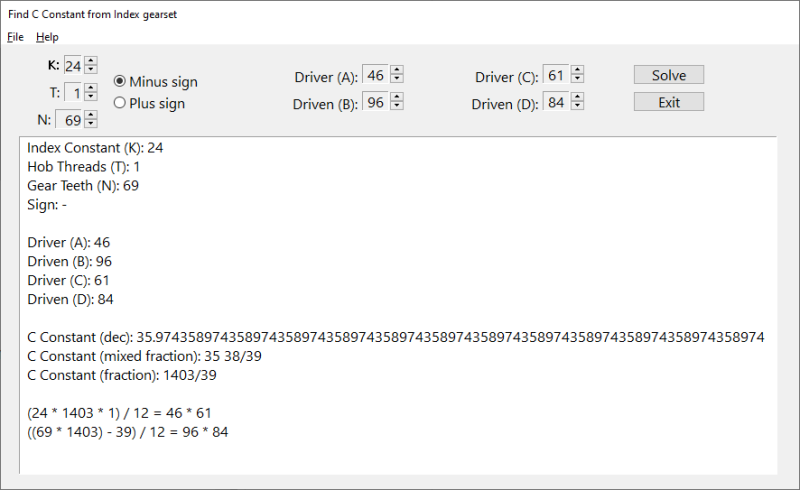

K = 24

C = 35 (~0.027" feed)

T = 1

N = 34

M = 0.075

Helix angle = 16

Diametral pitch 12

Change gears = 24 to 70

Index:

24 x 35 x 1 = 840 = 24 x 35

(35 x 34) - 1 = 1189 = 41 x 29

Feed:

25 x 32

67 x 33

More coming...

Formula for hobbing helical gears:

KCT

(CN) ± 1

K = machine index constant

C = C constant

T = number of threads on hob

N = number of teeth on gear

1 = absolute constant

M = feed constant

Sample:

K = 24

C = 35 (~0.027" feed)

T = 1

N = 34

M = 0.075

Helix angle = 16

Diametral pitch 12

Change gears = 24 to 70

Index:

24 x 35 x 1 = 840 = 24 x 35

(35 x 34) - 1 = 1189 = 41 x 29

Feed:

25 x 32

67 x 33

More coming...