How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gears centre distance problem.

- Thread starter bilal

- Start date

- Replies 9

- Views 2,060

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

Yan Wo

Stainless

- Joined

- Jan 22, 2014

- Location

- Highland, Utah, USA

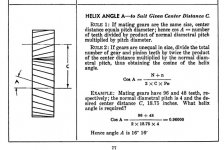

Add the two pitch diameters and take half of that - which will be center distance

Example:

4DP 48 teeth and 4DP 96 teeth

Have 12.000 and 24.000" pitch dias.

12 plus 24 = 36

Half of 36 = 18.000 center distance (if straight cut)

Gets more complicated if helical

View attachment 279538

Do you need to add a wee bit of clearance?

Do you need to add a wee bit of clearance?

I thought clearance was in the tooth form, and that using center distance is kind of a make-do.

Is that wrong?

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

I thought clearance was in the tooth form, and that using center distance is kind of a make-do.

Is that wrong?

Covered in infinite detail in Earle Buckingham's books - and others no doubt

EmGo

Diamond

- Joined

- Apr 14, 2018

Yes and no .... Thinning the teeth by cutting them deeper is perfectly acceptable, and it doesn't mess with the shape because all gear machines now generate the shape, and an involute curve is not picky.I thought clearance was in the tooth form, and that using center distance is kind of a make-do.

Is that wrong?

If you were using a space cutter, it probably would not be perfect but space cutters aren't perfect anyhow and the teeth aren't a perfect shape under load either, so in practice, no.

If you were doing cycloidal teeth then they'd be all messed up if you tried to cut them deeper to make backlash, it has to be in the cutter ... so in general, people don't cut cycloidal teeth, it's too much of a pain in the ass

For those non-involute weirdo shapes you'll have to ask Zahnrad, he likes that ... stuff

For the op's original question, I think the easiest way for him would be to do a span measurement and compare to standard dimensions. He could do it over wires, too, but that's more involved. The 'calculating center distance by counting teeth and dividing by the dp' method works okay if both gears are standard proportions. If they are drop-tooth or spread centers or in some other way non-standard, then the theoretical numbers won't work.

Unfortunately, non-standard in the gear world seems to be kind of standard

I think something that confuses people is the way we speak of theoretical things as if they were real. The fact is, gears do not have a pitch diameter until they are operating with another gear. And then, the pitch diameters are a function of the center distance and the numbers of teeth, not whatever the theoretical numbers are. It makes it easier to discuss but in Real Life (tm) the "pitch diameters" are almost never going to be the catalog numbers.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

machinistrrt

Stainless

- Joined

- Aug 15, 2008

- Location

- near Cleveland

I always follow these gear discussions with interest.... it seems like there's always at least *some* sorcery involved.

Thanks.

Thanks.

Zahnrad Kopf

Diamond

- Joined

- Apr 5, 2010

- Location

- Tropic of Milwaukee

For those non-involute weirdo shapes you'll have to ask Zahnrad, he likes that ... stuff

Hey! We do more Involute than not, but yeah... we do see more than our fair share of oddball* stuff.

Most likely, it's only because I'm the only one stupid enough not to say, "No" right out the gate.

*- Asymmetrical Tooth Forms and A LOT of Skip Tooth / Skip Space / Specific Alignment callouts / Non Standard Pitch Sizes ( ex: 14.56 DP or 1.19 Module ) / etc...

Unfortunately, non-standard in the gear world seems to be kind of standard

This. So much this. People really don't realize how true this is.

To the OP's question, as EG said - your answer is, "Yes." And, "No."

Assuming we are discussing Involutes, it really depends on whether one, the other, or both are Non-Standard. The other variable that exists is by how much EACH, INDIVIDUALLY are non-standard.

Is it backlash? Is it tooth Profile Modification? Is there a balance to the modification? Or, just one sided? And then, WHICH Van Keuren standard was used to measure them? ( which is actually one of the reasons that I like Span measurements - No effing around with figuring out what wire size to use. )

Believe it or not, there is actually a few pages dedicated to this in Machinery's Handbook. ( among a host of others )

This, combined with the previous answers is all you need to calculate the Center Distance. The biggest hurdle is being sure that you know HOW the gears differ from Standard.

Similar threads

- Replies

- 0

- Views

- 279

- Replies

- 57

- Views

- 3K