RC99

Diamond

- Joined

- Mar 26, 2005

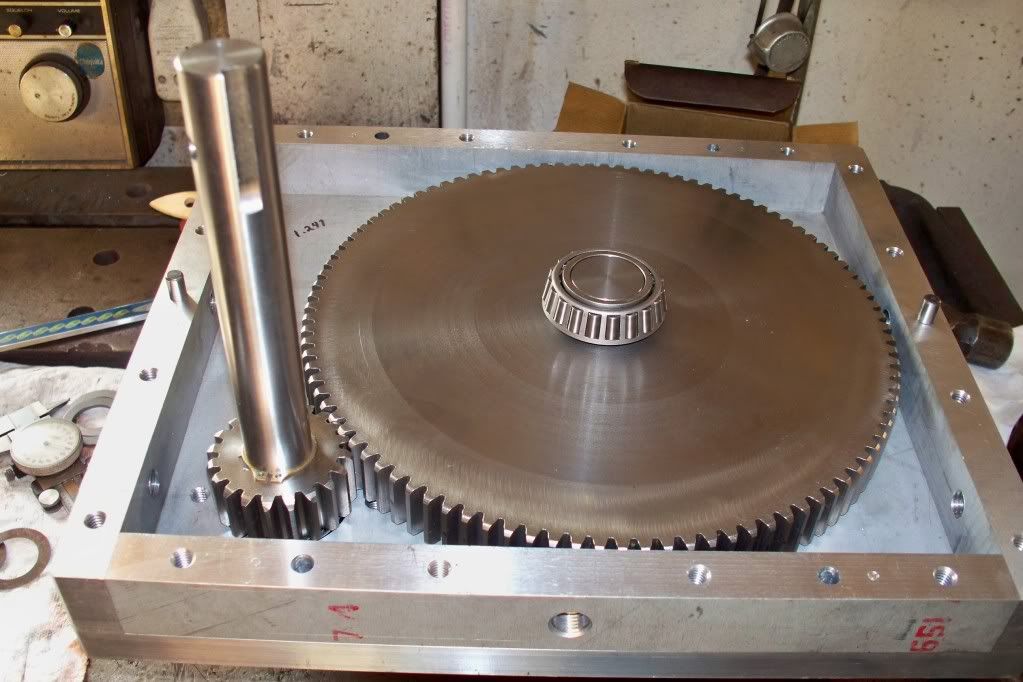

I need to make an inline reduction gearbox of close to 1.5:1 ratio to slow the output of a small 27hp diesel motor to 1500rpm to run a generator. No more then 50ft lb's torque on the input.

Are these incredibly complex things to build or just relatively basic so long as you have good common sense.

Are these incredibly complex things to build or just relatively basic so long as you have good common sense.