Sourced some parts for a small spindle project and would like to get some feedback on the tolerances. All steel parts of different high tensile qualities however not hardened (I think..). Housing is to be ID 80mm throughout and shaft is to be OD 40mm. Was planning to use 2x double angular contact bearings in the front and 1x ball bearing at the back, all greased. C-C distance between the two bearing positions is to be approx. 125mm. I'm not having high expectations so my goal is for now continous 5-6K rpm with 0,05 runout at approx. 50ºC.

As I wish to use available off the shelf components to keep the cost low and DIY factor high I have ended up with tolerances as stated below (both ID housing and OD shaft = Ground).

Do you guys think my clearances below are OK?

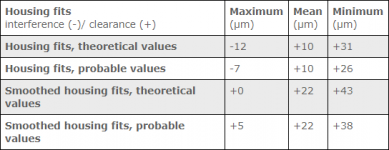

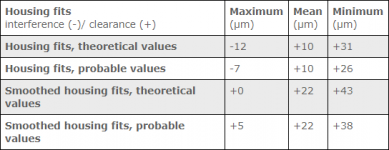

Between housing and outer bearing shell:

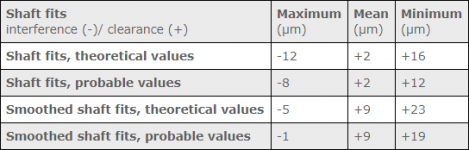

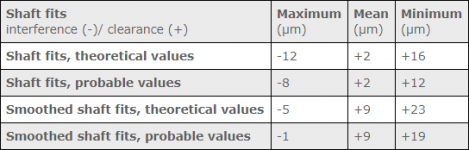

Between inner bearing shell and shaft:

As I wish to use available off the shelf components to keep the cost low and DIY factor high I have ended up with tolerances as stated below (both ID housing and OD shaft = Ground).

Do you guys think my clearances below are OK?

Between housing and outer bearing shell:

Between inner bearing shell and shaft: