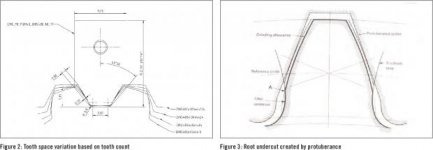

Question : I have to cut a gear with 54 teeth ( M1.5 PA20 ). This will need cutter #6 (34-54) . BUT I read a cutter is best for the low number of teeth and only an approximation for the top number. Then #6 will be best for 34 teeth. I am thinking it may be better to cut with #7 which is best for 55 teeth. Am I correct and if not , why not ?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.