gjrepesh

Cast Iron

- Joined

- Aug 30, 2002

- Location

- Royse City, TX

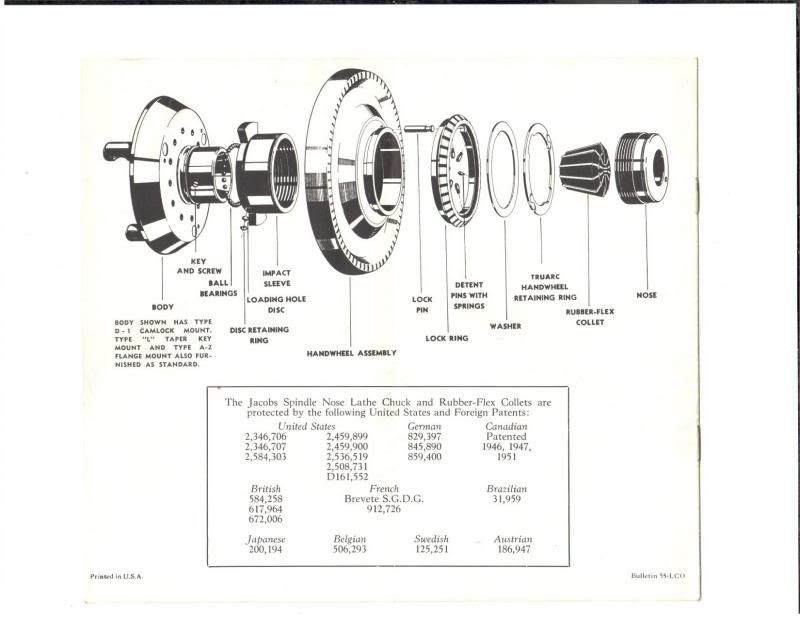

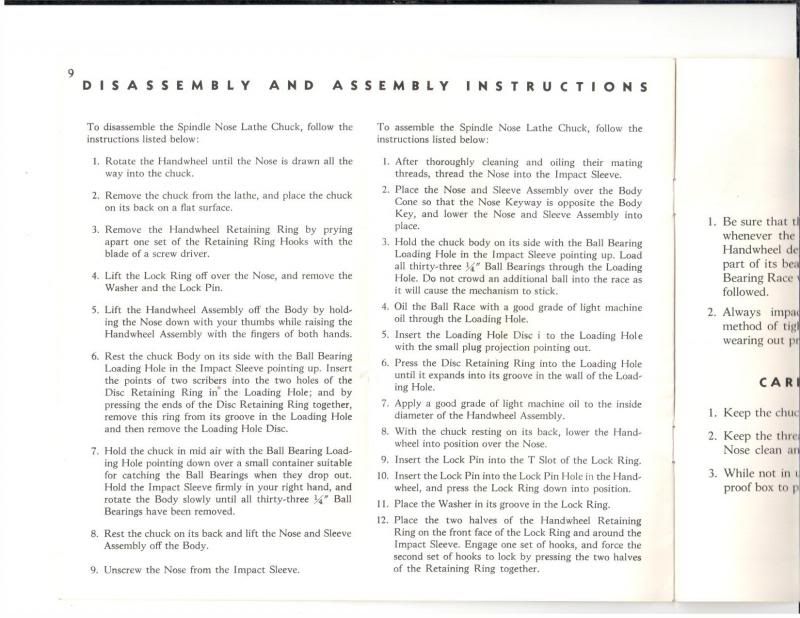

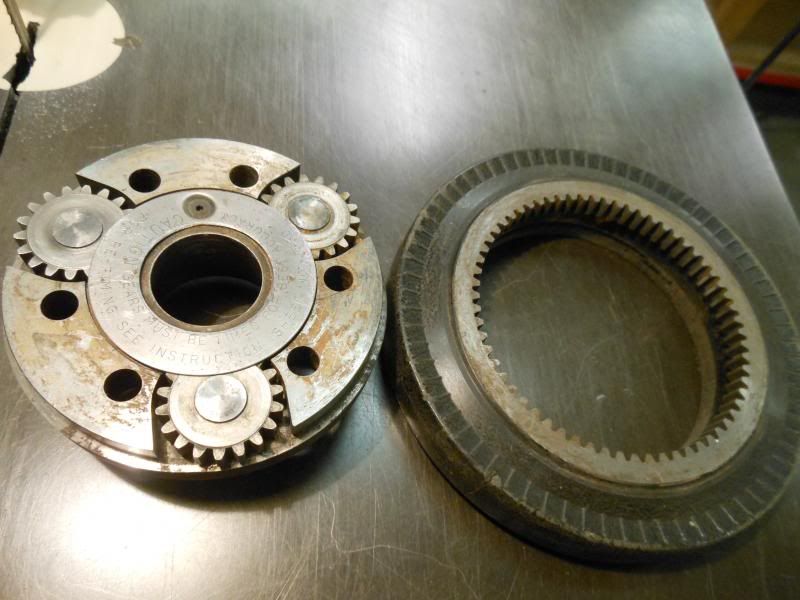

If you have taken apart and reassembled a Jacobs Rubber-Flex Collet Chuck Model 91, I would like your comments. I bought one for my Logan 14" lathe with 2 1/4-8 spindle. It threads on but needs to be fitted so that it will register. I am ok with this so far. I will need to take the chuck apart, though, to do the fitting. I see ball bearings and other assorted pieces in the parts diagram and would like instructions or tips so I don't mess something up. If it is just a matter of don't lose anything, that would be helpful. And tips on reassembly also. Needless to say, I don't have any instructions on this. Thanks.

Leave the impact parts assembled while fitting the back plate.

Leave the impact parts assembled while fitting the back plate.