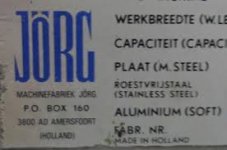

I'm buying a Jörg 50 inch 14 gauge shear. It looks like it's good quality, made in the Netherlands.

My question is, do you think this will cut a 48 inch piece of 16 gauge 304 stainless ok? I did some test cuts with smaller pieces (4 and 8 inch) of the 304 16 ga and it was fine. I'm just worried about the whole 48" width. Any idea? The blades look pretty clean.

My question is, do you think this will cut a 48 inch piece of 16 gauge 304 stainless ok? I did some test cuts with smaller pieces (4 and 8 inch) of the 304 16 ga and it was fine. I'm just worried about the whole 48" width. Any idea? The blades look pretty clean.