How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe Bar Support

- Thread starter Bradyz

- Start date

- Replies 6

- Views 1,065

dkmc

Diamond

- Joined

- Jan 13, 2002

"Out the side" ? Why would you want the bar supported out the side of the machine and not out of the back of the spindle?

You could just set a wimpy roller stock stand NEXT to the bar like this setup. Not very effective tho...

Lathe Bar Stock Accident - Whipping at high speed - YouTube

You could just set a wimpy roller stock stand NEXT to the bar like this setup. Not very effective tho...

Lathe Bar Stock Accident - Whipping at high speed - YouTube

I have a small GT27 lathe with a bar puller but need some kind of support out the side for 6' long bars. Could I just weld up an aligned DOM tube with a UHMW liner slightly larger than my stock off the side of the machine? Thoughts?

FredC

Diamond

- Joined

- Oct 29, 2010

- Location

- Dewees Texas

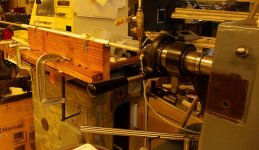

Here is an ugly bar support. Used it for the last 25 years with no issues. Base is a Traub screw machine,it has a tabletop bolted to the base with C-clamps holding the 2 X 6 in position. PVC pipe in a channel of the 2 by rounds it out. Your idea is OK make sure it clears any electrical box on that side and does not cut off access to belt adjustment or access to that end. A stable support on the outside end of your tube would be a good idea. The thing in the support is for introducing a little air into the spindle to keep chips and oil out of the collet when running second ops. The plastic bushing in the spindle sort of seals and allows most of the air to go thought the hollow collet stop.

FredC

Diamond

- Joined

- Oct 29, 2010

- Location

- Dewees Texas

Could not find the photos on the computer, but here is a link to an old thread post no 6 is a shop built bar feed. Ith is bolted to the machine and the outboard end sits on the floor. 20 plus years of use on this one.

https://www.practicalmachinist.com/...endations-lathe-356212/?highlight=bar+feeders

A couple more notes. the attached photo here shows the electrical box of the machine with the shop built bar feed. I cut off the base that rested on the floor as it was in the way of getting into the electrics, every time I went into that box I would have to realign the bar feed. Now the support bolted to the cabinet supports that end.

Like Dkmc said be safe, think it out before you spin it up.

https://www.practicalmachinist.com/...endations-lathe-356212/?highlight=bar+feeders

A couple more notes. the attached photo here shows the electrical box of the machine with the shop built bar feed. I cut off the base that rested on the floor as it was in the way of getting into the electrics, every time I went into that box I would have to realign the bar feed. Now the support bolted to the cabinet supports that end.

Like Dkmc said be safe, think it out before you spin it up.

I have screw machines set up this way. My machines came with stands, but could use a heavier "deadman" stand on bigger material.

I also have a GT27 and will most likely be setting it up with the same setup you speak of. Until I decide to get a magazine style loader.

Just make sure the tube doesnt sway at all during run time. As long as it is straight it will work just fine.

Good luck.

I also have a GT27 and will most likely be setting it up with the same setup you speak of. Until I decide to get a magazine style loader.

Just make sure the tube doesnt sway at all during run time. As long as it is straight it will work just fine.

Good luck.

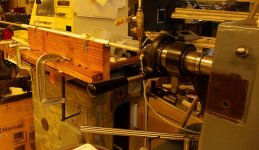

Some are made a bit fancy-er for ease of use.

I have one on a W&S 2ab that swings towards the front for loading.

The "Rearmost" support is a trunnion, and the front tube support is a "V" block

with a clamp.

I have one on a W&S 2ab that swings towards the front for loading.

The "Rearmost" support is a trunnion, and the front tube support is a "V" block

with a clamp.

Attachments

Similar threads

- Replies

- 35

- Views

- 3K