My employer is looking at replacing our Potomac laser mill. The laser on it is basically dead and people much more knowledgeable about lasers than me have determined that rebuilding the laser is not an option and replacing the laser on a 20 something year old machine may not be a good idea, if even possible.

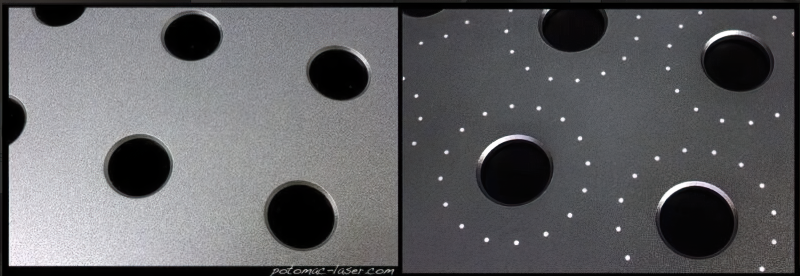

I will freely admit that I know nothing about lasers other than how to program and run this specific machine. This machine has been used to cut materials such as stainless, brass, tungsten, kapton, etc, in thicknesses from .0005in to a practical max of .005in. Anything beyond that starts exponentially increasing the number of passes required. The machine uses a camera with crosshairs to locate the work piece and set the focal length, and appears to be capable repeatability better than 5 micron (.0002in). I am not sure that this level of precision is required for most of the work we do with this machine but occasionally it is useful.

I really have no idea where to start looking for a machine of similar capabilities and what the price range would be. I know the Potomac laser mill we currently have was $325,000ish 20 years ago but I don't know if prices would have come down any.

If current lasers would allow us to cut thicker materials without losing the ability to cut thin materials that would be fantastic but most of what this machine has been used for is prototype circuits, vapor deposition masks, and making tiny reaction wells.

If there is any other information that would be helpful please let me know and I will try to provide it.

I put this in the generals subforum since it didn't seem to fit with the fabrication subforum but if there is a better place please move it.

Thanks in advance.

I will freely admit that I know nothing about lasers other than how to program and run this specific machine. This machine has been used to cut materials such as stainless, brass, tungsten, kapton, etc, in thicknesses from .0005in to a practical max of .005in. Anything beyond that starts exponentially increasing the number of passes required. The machine uses a camera with crosshairs to locate the work piece and set the focal length, and appears to be capable repeatability better than 5 micron (.0002in). I am not sure that this level of precision is required for most of the work we do with this machine but occasionally it is useful.

I really have no idea where to start looking for a machine of similar capabilities and what the price range would be. I know the Potomac laser mill we currently have was $325,000ish 20 years ago but I don't know if prices would have come down any.

If current lasers would allow us to cut thicker materials without losing the ability to cut thin materials that would be fantastic but most of what this machine has been used for is prototype circuits, vapor deposition masks, and making tiny reaction wells.

If there is any other information that would be helpful please let me know and I will try to provide it.

I put this in the generals subforum since it didn't seem to fit with the fabrication subforum but if there is a better place please move it.

Thanks in advance.