vonleyser

Cast Iron

- Joined

- Nov 23, 2008

- Location

- Brookshire,Texas USA

Customer has a 1941 bliss 60 ton press model 21-1/2 that needs a new

(connection screw)basically this looks like a trailer ball for a hitch, except it is much larger, 4" diameter threads, about 18" long, he wants

one made with 6 " more of thread length.

My question is for the best type of material to use for this set up.

are we looking at 4140, 4340 ?

Don't have any pictures yet, but you can get an idea of by searching.

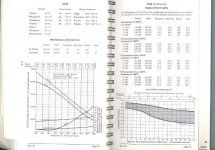

Will add more as I find out. here is a picture of the parts break down

#20 is what is needing replaced

After seeing this in person there is another question.

Inside the larger piece that captures the ball is something? a wear split ring/bushing

that also looks like it needs to be replaced.

Any idea how this comes apart?

(connection screw)basically this looks like a trailer ball for a hitch, except it is much larger, 4" diameter threads, about 18" long, he wants

one made with 6 " more of thread length.

My question is for the best type of material to use for this set up.

are we looking at 4140, 4340 ?

Don't have any pictures yet, but you can get an idea of by searching.

Will add more as I find out. here is a picture of the parts break down

#20 is what is needing replaced

After seeing this in person there is another question.

Inside the larger piece that captures the ball is something? a wear split ring/bushing

that also looks like it needs to be replaced.

Any idea how this comes apart?

Attachments

Last edited: