farmersamm

Cast Iron

- Joined

- Feb 26, 2008

- Location

- oklahoma

Dealing with less than solid substrate, and less than acceptable machine. (Get used to it, it's the wave of the future, sad to say) The MAGA boys got ya to fighting amongst yerselves, while they steal the country.

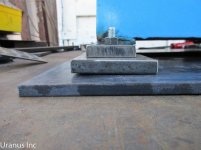

Problem is to make this suitable for a solid base.

Problem is to make this suitable for a solid base.

Some crap welds to deal with.

Some crap welds to deal with.

Cut them out, grind a V, and fill it. Solid connection.

This is welding, for y'all that only sit on stools.

Problem is to make this suitable for a solid base.

Problem is to make this suitable for a solid base. Some crap welds to deal with.

Some crap welds to deal with.Cut them out, grind a V, and fill it. Solid connection.

This is welding, for y'all that only sit on stools.